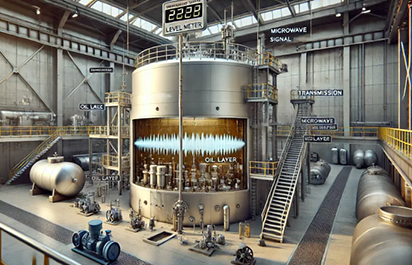

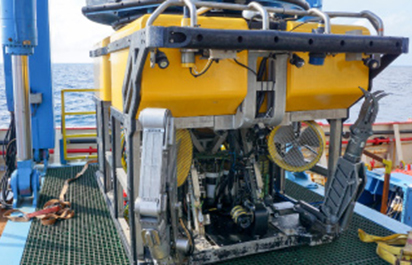

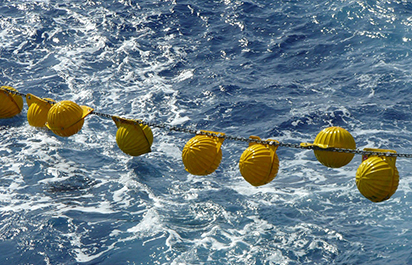

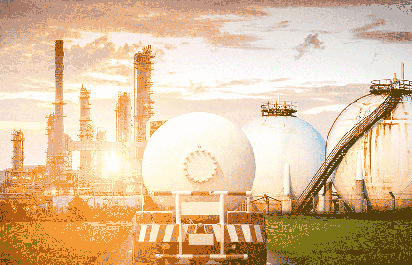

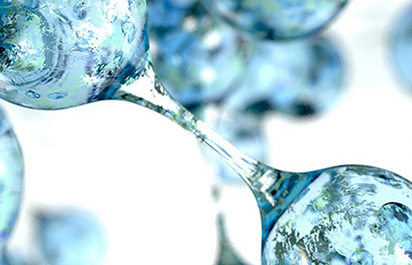

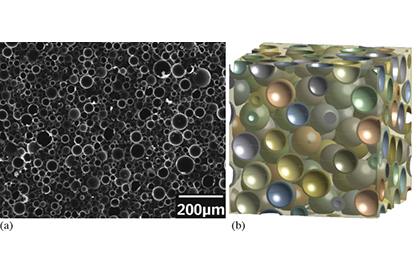

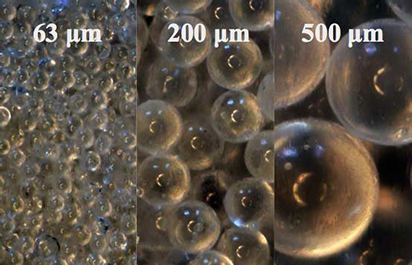

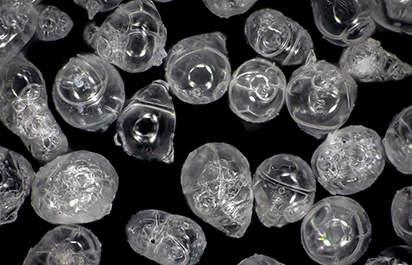

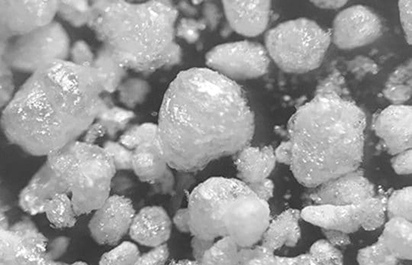

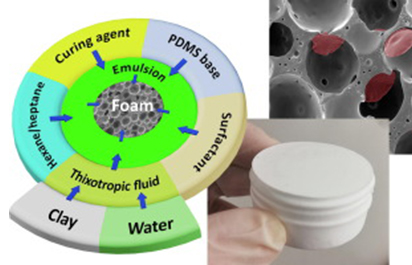

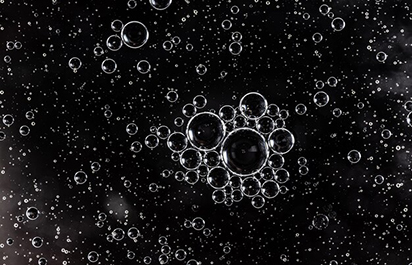

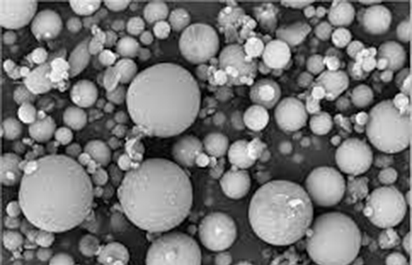

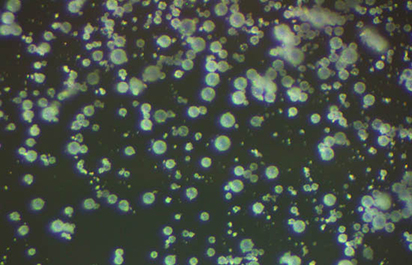

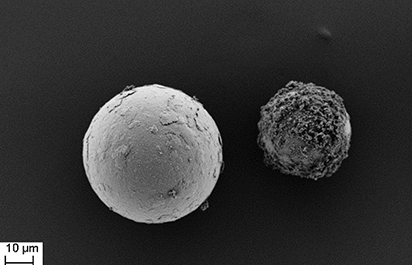

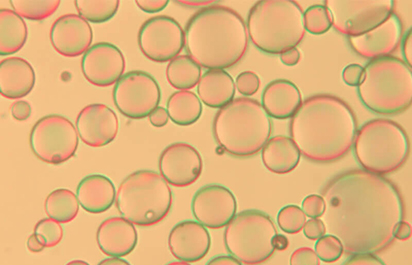

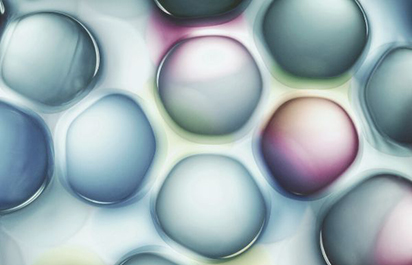

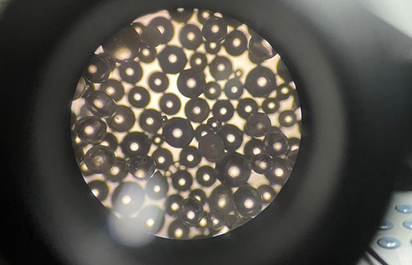

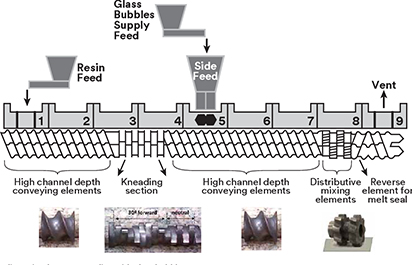

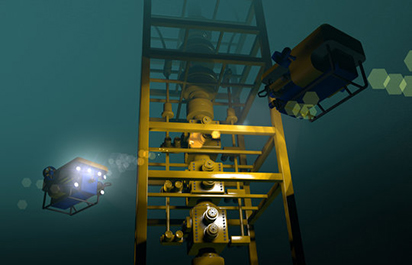

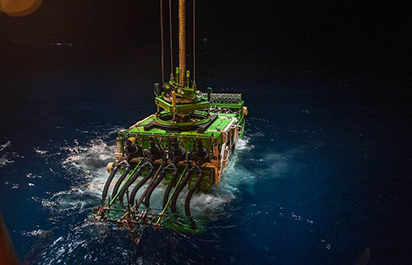

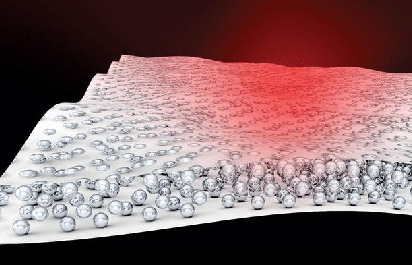

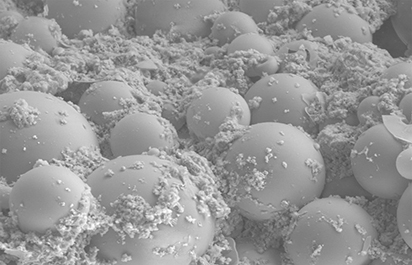

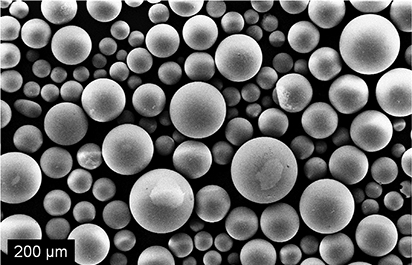

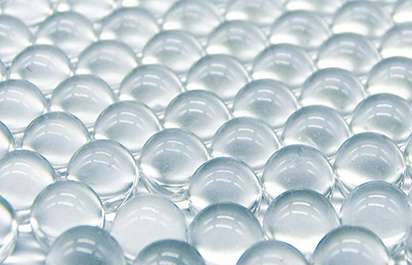

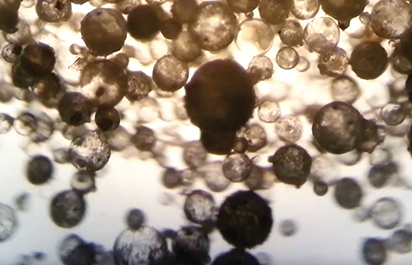

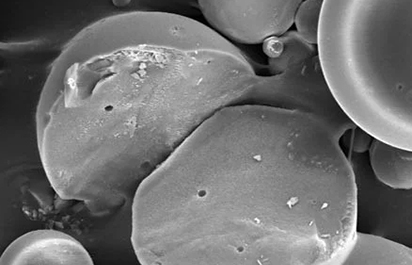

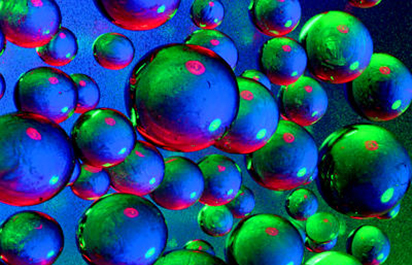

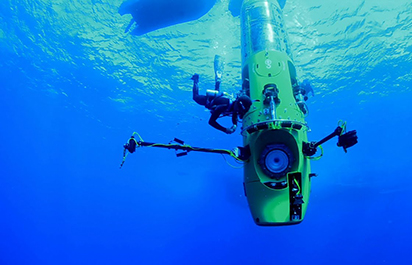

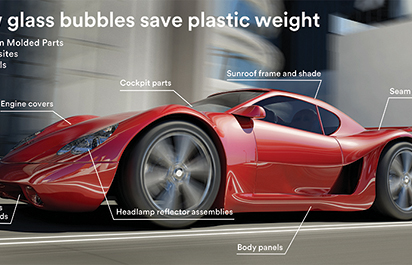

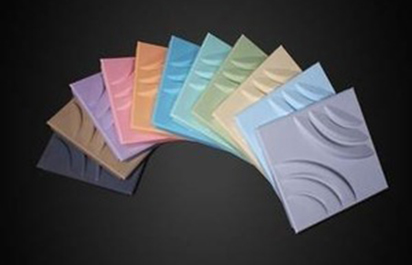

Glass Bubbles for Oil & Gas Buoyancy Modules

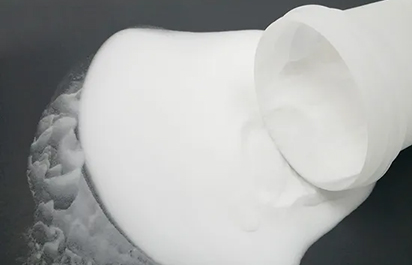

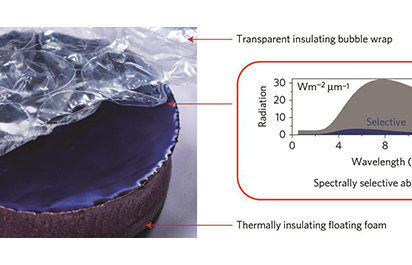

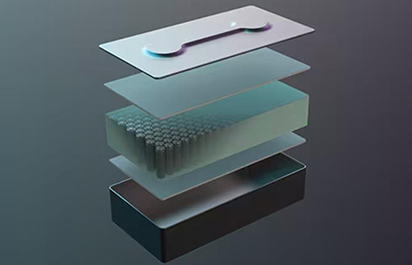

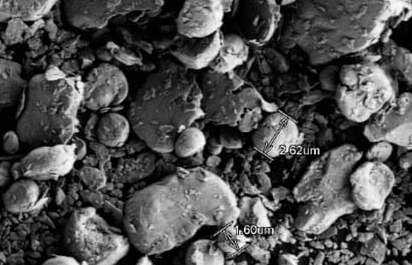

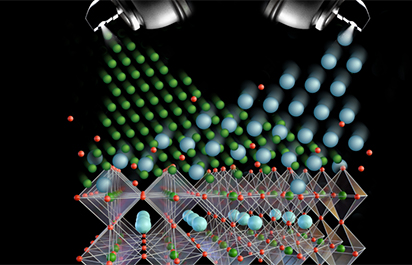

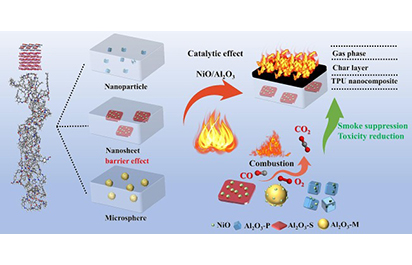

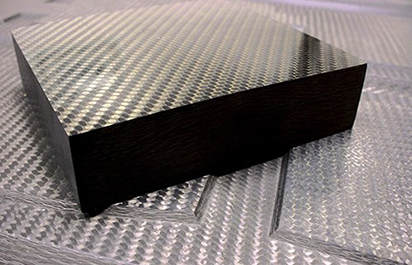

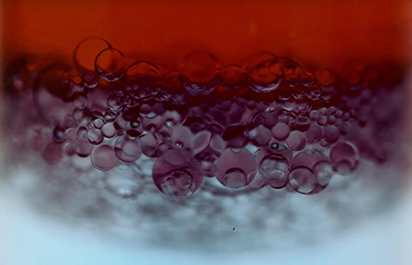

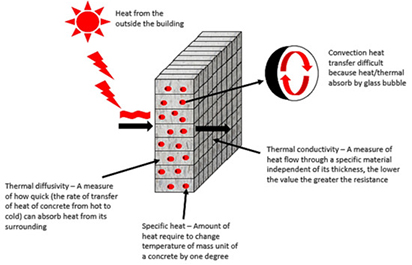

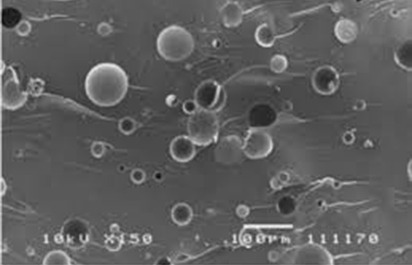

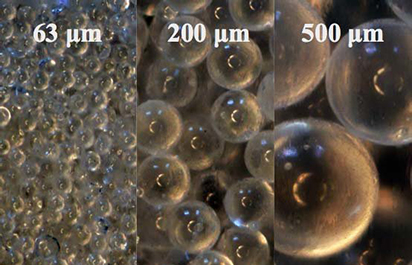

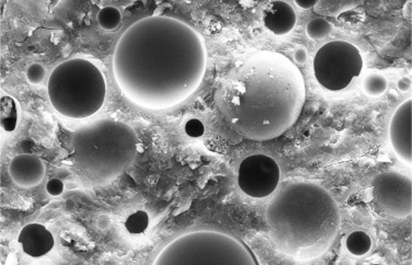

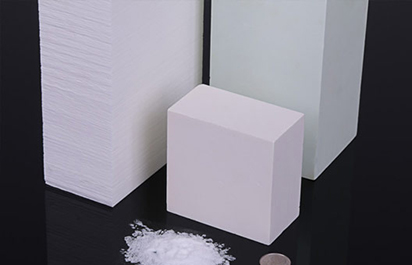

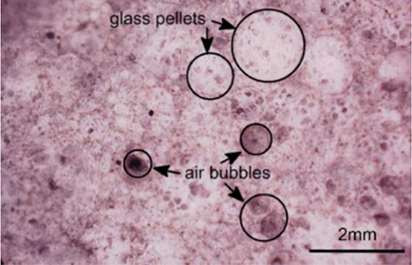

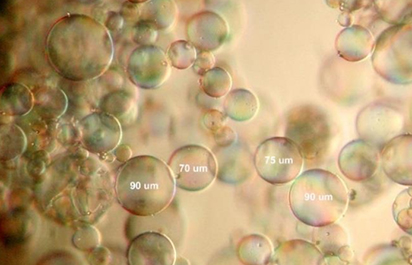

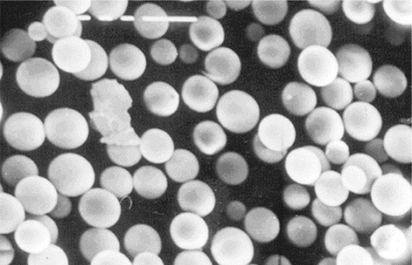

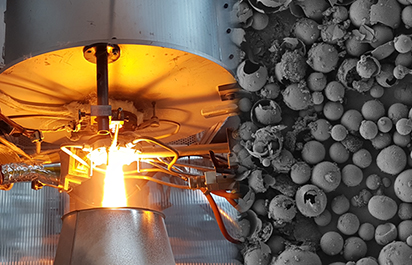

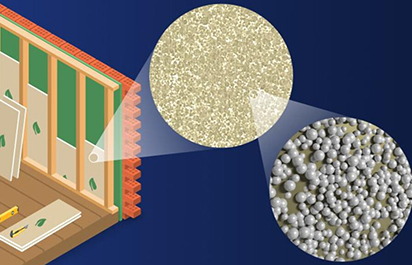

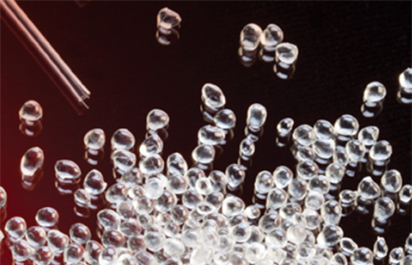

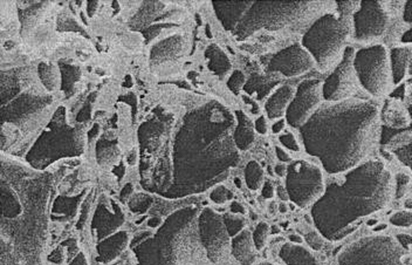

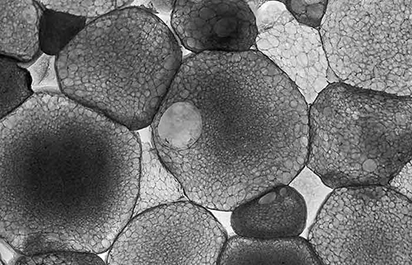

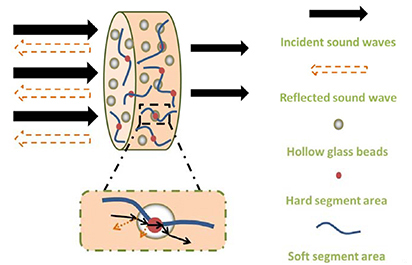

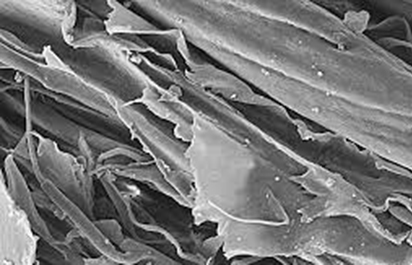

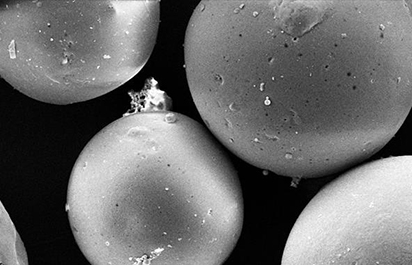

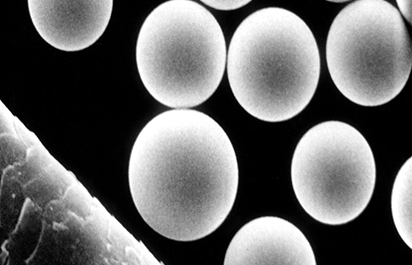

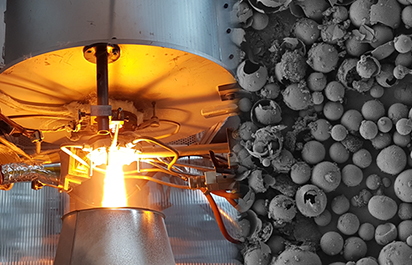

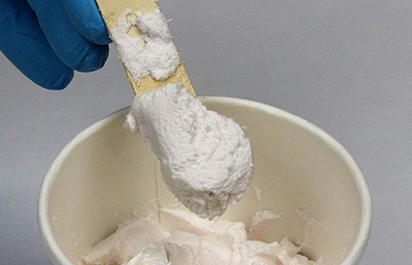

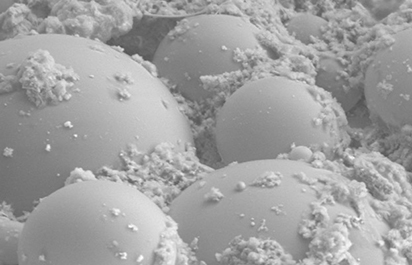

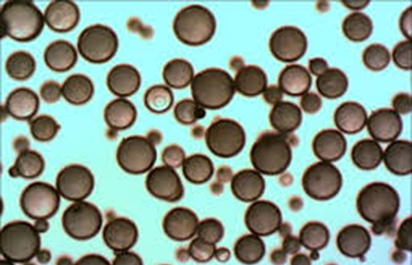

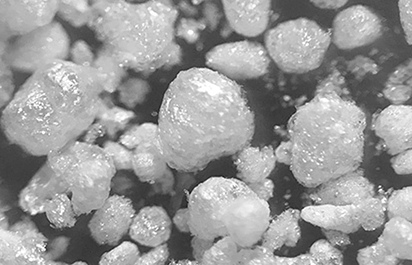

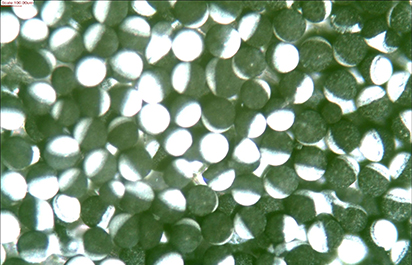

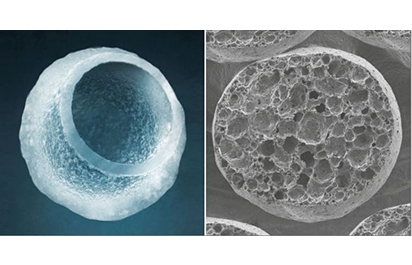

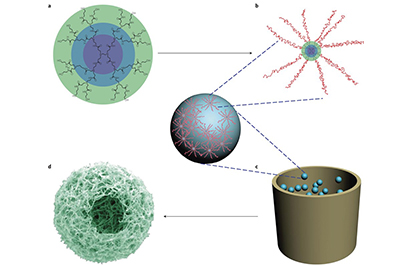

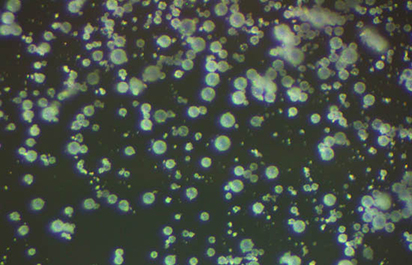

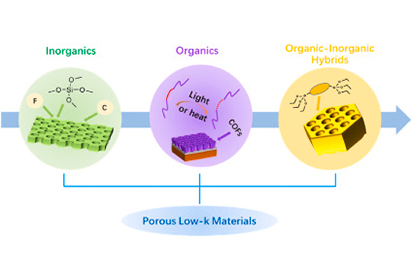

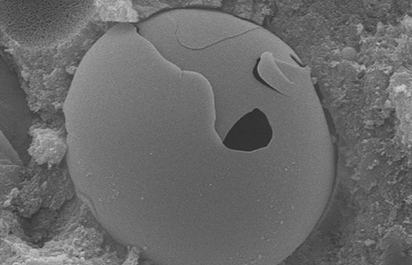

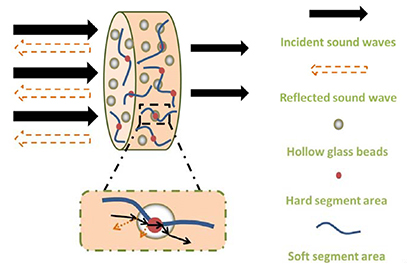

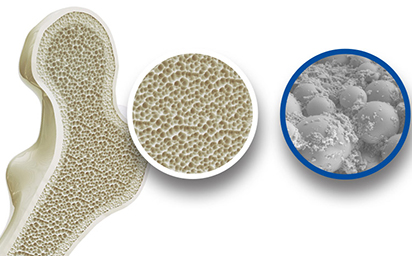

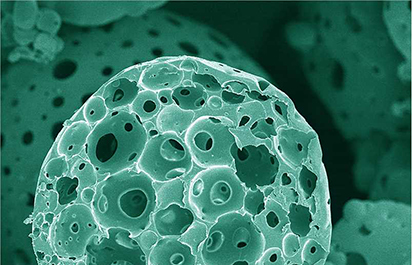

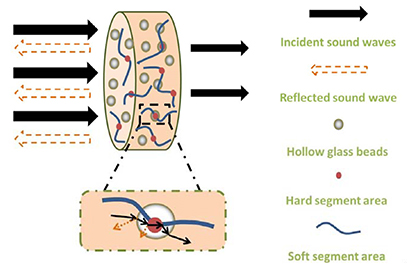

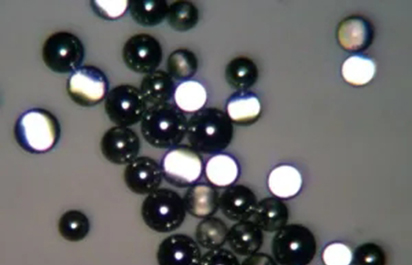

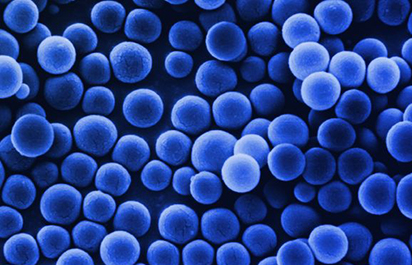

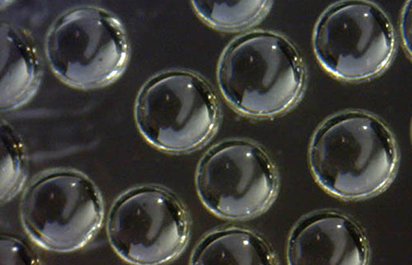

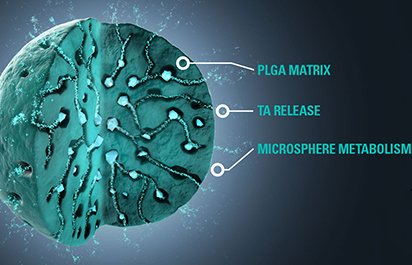

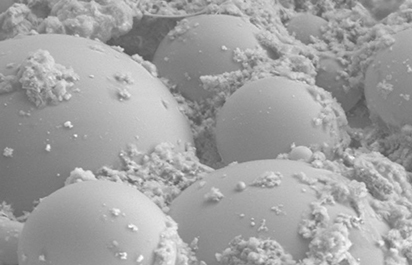

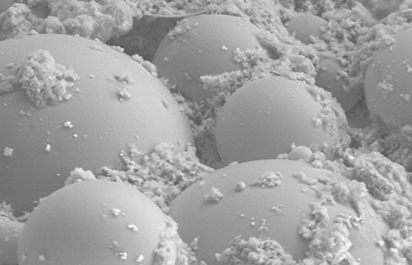

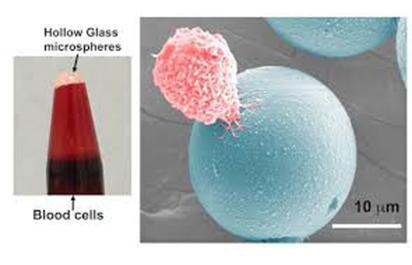

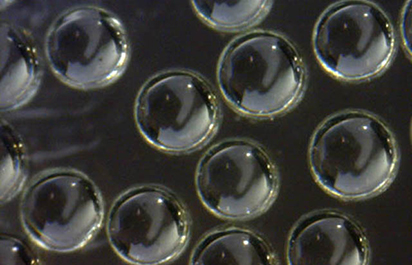

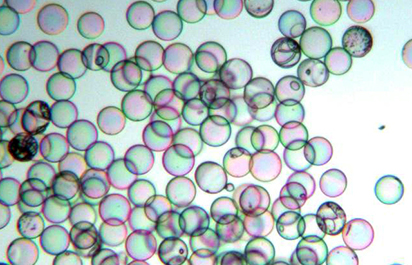

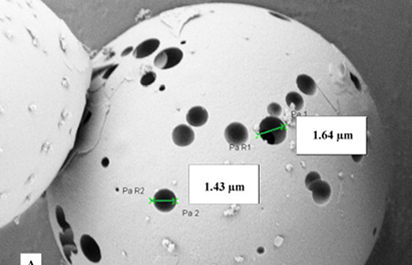

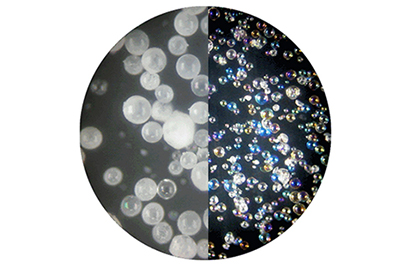

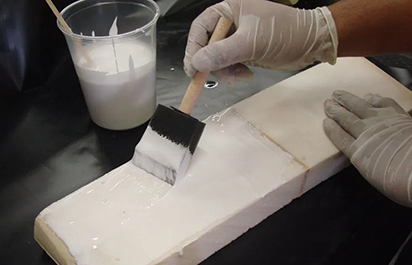

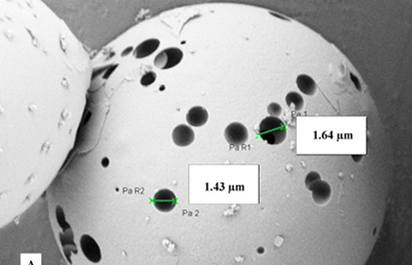

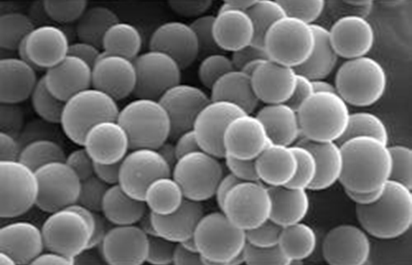

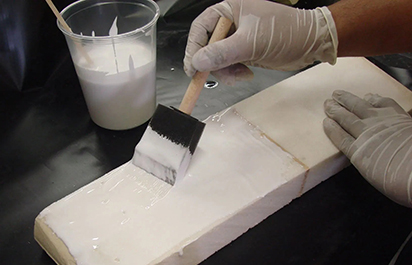

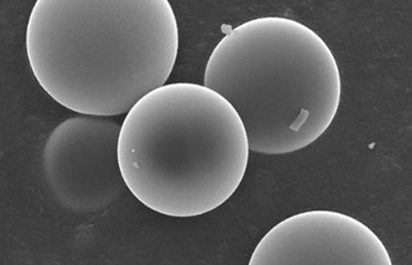

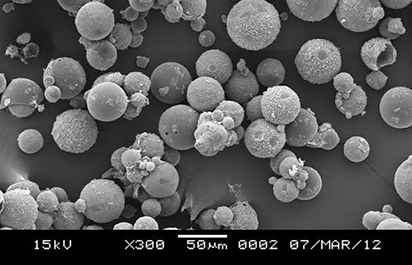

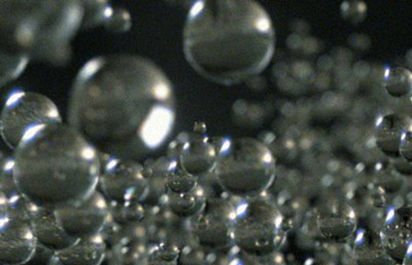

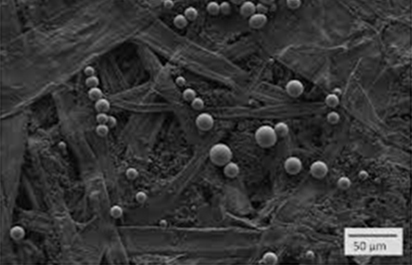

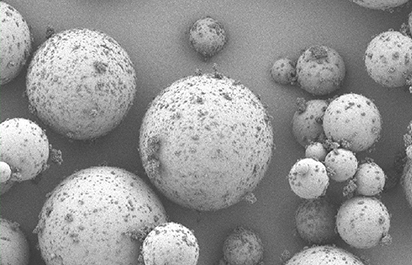

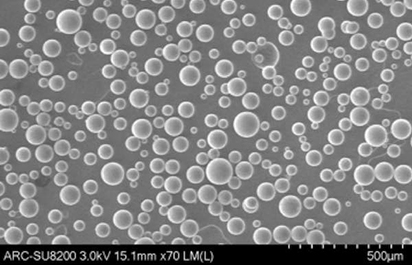

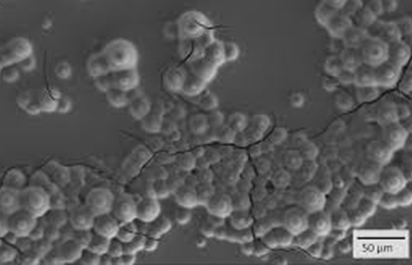

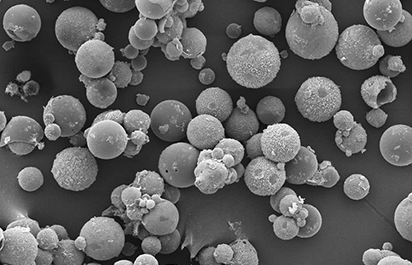

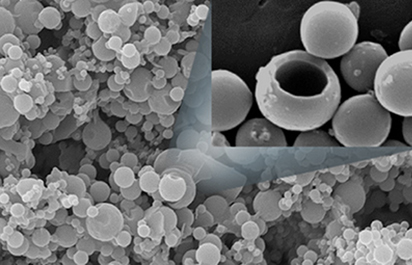

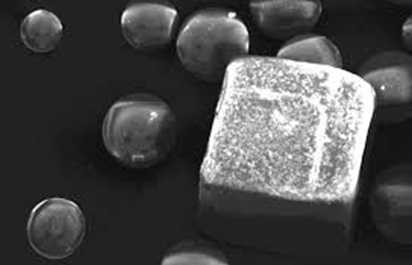

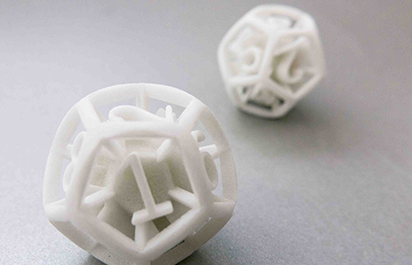

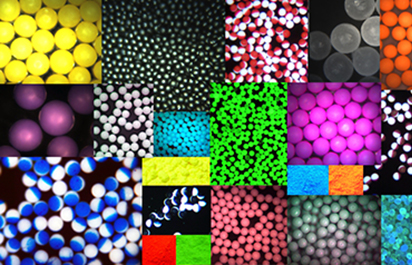

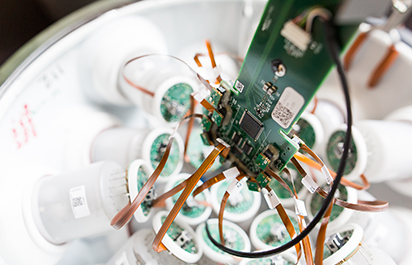

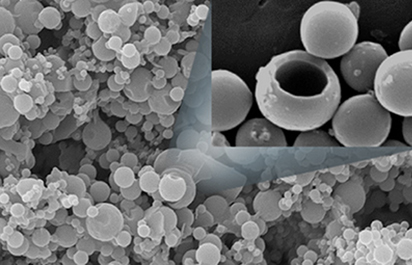

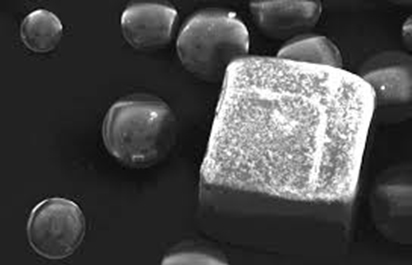

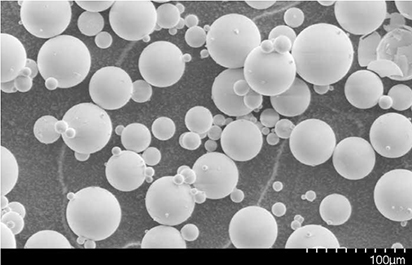

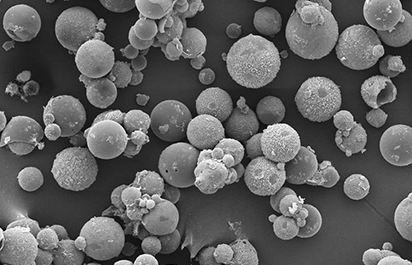

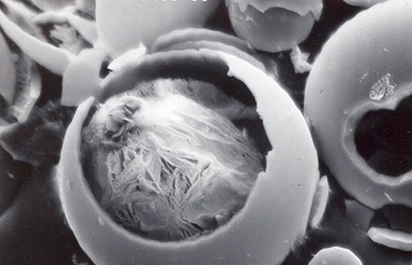

For offshore operators seeking reliable and efficient buoyancy solutions, glass bubble-reinforced syntactic foam remains one of the most advanced material technologies available....

Learn more >