It will have a significant influence on end products when we choose the glass microspheres reasonable. Therefore, to choose a suitable grades for our customers is very important. We can offer comprehensively product series to meet your demands.

| Type | True Density | Crush Strength (Psi) | Crush Strength (MPa) | Particle Size(μm) | Application Suggestion | ||

| (g/cm³) | Minimum Fractional Survival≥80% | Minimum Fractional Survival≥80% | D10≤ | D50≤ | D90≤ | ||

| H32 | 0.30~0.34 | 2000 | 14 | 25 | 55 | 105 | With the performance of hydrophilicity and lipophilicity,and widely used in composite material、adhesive and painting etc. |

Glass bubble & Hollow glass microsphere's applications are in the fields of thermal insulation coating, putty, plastic casting polyester, FRP, SMC(BMC), radome, synthetic foam, adhesives, printed circuit board substrate, RTM, bowling, fan blades, & caulking materials, emulsion explosives, golf, sealant, pipeline insulation materials, artificial marble, PVC, low density oil drilling, light cement, and other deep-sea buoy etc.

To solve industrial problems

Application of hollow glass microspheres in paint

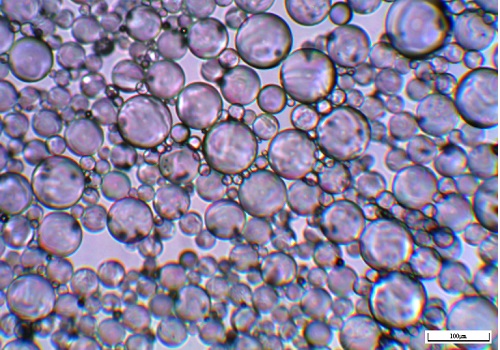

Hollow glass microspheres have the smallest surface area and low oil absorption rate, can significantly reduce the consumption of other components in paint.

The vitrified surface of glass microspheres can realize the chemical corrosion resistant, and reflexaction on light. Therefore, the paint can prevent from fouling, corrosion, UV, yellowing and scratching etc.

Thin gas inside the hollow glass microspheres with compact arrangement, makes low thermal conductivity, so that paint coating has a very good effect on heat insulation.

Hollow glass microspheres can effectively enhance the fluidity and smoothness of coating.

Hollow glass microspheres contain gas inside, so it has a good contractility resistance to hot and cold, thus enhancing the flexibility of coating, greatly reducing the cracking and peeling of the coating due to thermal expansion and contraction.

On premise of high filling level, the viscosity of paint will not be significantly increased, thus reducing the usage of solvents. It can reduce toxic gas emissions in the process of painting, and VOC indicator can be effectively reduced.

Dosage recommendation:The addition is normally about 10-20% of the total weight. Adding methods are proposed as follows: Last step. The hollow glass microspheres are proposed to add at the last step, and dispersed with low-speed, low shearing force mixing equipment. Due to its good liquidity,small friction, so it willeasily dispersed into mixture to completely keep wet within a short time. Through slightly extending mixing time can achieve uniform dispersion. Hollow glass microspheres are inert and non-toxic. Due to its light weight, attention should be specially paid when adding. We recommend adding the microspheres by step, that is, the addition quantity is 1 / 2 of the remaining beads each time. It can well avoid the microspheres floating into the air and make it disperse even more completely.

Application of hollow glass microspheres in Putty

Compared with the traditional putty, the new type one adding with HGS owns the advantages as follows:

Easy preparation and production, the HGS can be well mixed by a simple low-speed mixer. Its product has a feature of light weight and large volume.

Compared with the ordinary putty, new putty with 5% of hollow glass microspheres, can replace 10 ~ 20% of talc, calcium carbonate, bentonite. Its volume can also be increased 15~25% than that of ordinary putty,and saving resin about 8%.

The oil absorption rate of HGS is much less than that of talc and other fillers. So it has a significantly lower viscosity.

Putty with HGS can be easily polished with advantages of time saving, labor-saving and dust reduction.

Application of hollow glass microspheres in the artificial marble products

The products filled with hollow glass microspheres have advantages of light weight, smooth and beautiful appearance, and lower cost.

Increase heat resistance;

2. Lower weight by 20% -35%;

3. Easier processing (drilling, sawing, grinding);

4. Easy polishing, high surface finish quality, lower tool wear resistance;

5. Reduce the costs of packaging and transport;

6. faster module flipping to increase productivity

7. Anti-shrinkage, warpage resistance, improving cracking resistance ability, reducing breakage rate.

8. Reduce the consumption of catalyst

Application of hollow glass microspheres in explosive

The density regulators commonly used in the Emulsion explosives are expanded perlite and chemical blowing agents. The first one has shortcomings of explosive effects limited by its size, strength and oil resistance, lower explosive performance, short-term storage; The second one has the disadvantage of the density of explosives difficult to control, short-term storage and aftereffects. With addition of hollow glass microspheres in the emulsion explosive, all its shortcomings and disadvantages can be overcome. The performance of the detonation is greatly improved and the storage stability is significantly increased. It mainly adopts the sensitization of hollow glass microspheres. Hollow glass microsphere have advantages of low density, low thermal conductivity, low oil absorption rate, particle size and chemical composition control, which makes it highly suitable as emulsion explosive sensitizer. It has significantly improved with less and detonation performance, enhance the storage stability characteristics.

Application of hollow glass microspheres in the exploitation of oil and gas fields

Hollow glass microspheres itself is inert without pollution. As a continuous medium, low density drilling fluid with addition of hollow glass microspheres was incompressible, and all wells are uniform in density. Sludge cakes formed have good lubrication, reducing the risk of sticking. It is technically infeasible for drilling large deviated wells and horizontal wells since the recycled micro-foam and air drilling technology can not deliver MWD signal. However, hollow glass microspheres have an irreplaceable advantage for it can not affect the system signal.

Hollow glass microspheres have a good rolling performance, and it can increase the drilling rate, and significantly improve the drilling effectively.

Drilling fluid with hollow glass microspheres has feature of high temperature resistance, high pressure resistance, stability, durability, and can be recycled.

With the increase of pressure, low-density slurry cementing with hollow glass microspheres were adopted to consolidate the wells to prevent or reduce leakage, increase the cement top. It plays a significant role in increasing the exploration reserves, improving single well production, and effectively developing underground oil and gas resources so as to solve complex problems.

High-performance Hollow Glass Microspheres are lightweight, high-strength, hollow multifunctional inorganic non-metallic material, which is a new type of strategic new material encouraged and supported by the State. The products have excellent features of light weight, large volume, low thermal co...

Learn More>>High-performance Hollow Glass Microspheres are lightweight, high-strength, hollow multifunctional inorganic non-metallic material, which is a new type of strategic new material encouraged and supported by the State. The products have excellent features of light weight, large volume, low thermal co...

Learn More>>It will have a significant influence on end products when we choose the glass microspheres reasonable. Therefore, to choose a suitable grades for our customers is very important. We can offer comprehensively product series to meet your demands....

Learn More>>It will have a significant influence on end products when we choose the glass microspheres reason-ably. Therefore, to choose a suitable grades for our customers is very important. We can offer com-prehensively product series to meet your demands....

Learn More>>