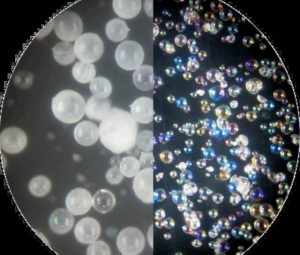

Hollow glass microspheres are glass microspheres with low density, light texture, and high strength. Due to its hollow nature, compared to traditional glass microspheres, it has the characteristics of light weight, low density, and good insulation properties, making it the primary raw material for thermal insulation coatings. Due to its small particle size, which is equivalent to or approximately exceeds the fineness of traditional filler materials used in coatings, it is possible to directly add filler materials into the coating system, so that the coating produced by coating solidification has thermal insulation properties. Usage characteristics; Efficient filling, low oil absorption, low density, and the addition of 5% (wt) can increase the product by 25% to 35%, thereby not increasing or even reducing the unit volume cost of the coating. Hollow glass microsphere particles are enclosed hollow spheres that are added to the coating to create many micro independent insulation chambers, thereby significantly improving the insulation performance of the coating to heat and sound, playing a very good role in insulation and noise reduction. Make the coating have better waterproof, stain resistant, and corrosion resistant properties. The chemically inert surface of the microspheres is resistant to chemical corrosion. When used as a film, the particles of the glass microspheres are arranged in a compact order, resulting in low porosity, which creates a protective film on the coating surface that has a blocking effect on moisture and corrosive ions, playing a very good protective effect.

The spherical structure of hollow glass microspheres has a very good dispersion effect on impact resistance and stress, and when added to coatings, it can greatly improve the resistance to external force impact characteristics of coatings, and also reduce the stress cracking caused by thermal expansion and contraction of coatings. Better whitening and covering effects. White powder has a better whitening effect than regular pigments, effectively reducing the use of other expensive fillers and pigments (compared to titanium dioxide, the volume cost of microspheres is only 1/5 of that), and reasonably strengthening the adhesion of the coating. The low oil absorption characteristics of glass microspheres enable more resin to participate in film formation, thereby increasing the adhesion of the coating by 3-4 times. Adding 5% micro beads can increase the coating density from 1.30 to within 1.0, significantly reducing the coating weight and preventing wall coating peeling.

Jinan Hongtu New Materials Co., Ltd., a liquid flame retardant manufacturer, was founded in 2020. It mainly produces, develops, and sells halogen-free flame retardants, liquid halogen-free flame retardants, brominated environmentally friendly flame retardants, environmentally friendly flame retardant masterbatches, PP transparent nucleating agents, lubricants, and other plastic and coating additives; And plasticizing enterprises for plastic peripheral products. Plastic and coating additives include: PP nucleating agent series – PP transparency enhancing and PP rigidity enhancing nucleating agents and nucleating agent masterbatches; PVC plastic additive -1. PVC liquid/powder flame retardant 2. PVC bright lubricant 3. PVC modifier 4. PVC transparent heat stabilizer 4. Coating additive – BYK leveling agent; BYK defoamer; BYK dispersant and coating conductive agent, drying agent; Draping agents, tactile agents, etc.

Posts tagged ‘glass microspheres’

Glass microspheres, also known as glass beads or microbeads, are small spherical particles made of glass. They find diverse applications across various industries due to their unique properties. Here are some application prospects of glass microspheres:

- Fillers and Extenders: Glass microspheres can be used as fillers and extenders in various materials, including paints, coatings, adhesives, and plastics. They help improve the properties of these materials, such as reducing density, enhancing strength, improving thermal and acoustic insulation, and increasing wear resistance.

- Cosmetics and Personal Care Products: Glass microspheres are used in cosmetics and personal care products to provide benefits such as light diffusion, texture improvement, and visual effects. They can add a smooth and silky feel to creams, lotions, and makeup products, and help in achieving a more even skin tone by diffusing light.

- Automotive and Aerospace Industries: Glass microspheres are employed in the automotive and aerospace sectors for various applications. They are used in lightweight materials and composites to reduce overall weight, improve fuel efficiency, and enhance impact resistance. In automotive paints, glass microspheres help create a smoother finish and improve scratch resistance.

- Reflective Road Markings and Traffic Paints: Glass microspheres are a key component in reflective road markings and traffic paints. They are embedded in the paint or adhesive to enhance the visibility of road markings, signs, and traffic lines by reflecting light from vehicle headlights. This improves safety and visibility, especially during nighttime driving conditions.

- Thermal Insulation: Glass microspheres with low thermal conductivity are used in thermal insulation materials. They can be incorporated into building materials, coatings, and insulating foams to enhance their thermal insulation properties. These microspheres reduce heat transfer and improve energy efficiency in buildings and industrial applications.

- Medical and Biotechnology Applications: Glass microspheres are utilized in medical and biotechnology fields for various purposes. They can be used as carriers for drug delivery systems, where drugs are encapsulated within the microspheres and released in a controlled manner. Glass microspheres are also employed in diagnostics, microscopy, and flow cytometry as calibration standards and reference materials.

- Electronics and Displays: Glass microspheres find application in the electronics and display industries. They can be used as spacers in liquid crystal displays (LCDs) and touchscreens, providing uniform gap control between layers. Glass microspheres with conductive coatings are utilized in printed circuit boards (PCBs) for signal transmission and electrical insulation.

- Oil and Gas Industry: Glass microspheres are used in the oil and gas industry for applications such as cementing and well completion. They help improve cement slurries, providing better control of density, thermal insulation, and reducing the risk of gas migration.

These are just a few examples of the application prospects of glass microspheres. With their versatility and unique properties, glass microspheres continue to find new applications in various industries, contributing to advancements in materials, technologies, and product performance.

Glass microspheres are tiny spherical particles made of glass that have a diameter ranging from a few micrometers to a few millimeters. They are used in a variety of applications in different industries, such as:

- Fillers and extenders: Glass microspheres are used as fillers and extenders in various materials such as polymers, paints, coatings, and adhesives to improve their properties such as strength, durability, and viscosity.

- Cosmetics: Glass microspheres are used in cosmetics and personal care products as exfoliants, providing a gentle scrubbing effect.

- Biomedical applications: Glass microspheres are used in biomedical applications such as drug delivery, tissue engineering, and medical imaging.

- Oil and gas industry: Glass microspheres are used in the oil and gas industry for hydraulic fracturing or “fracking.” They are added to drilling fluids and pumped into the well to keep fractures open and increase oil and gas recovery.

- Aerospace industry: Glass microspheres are used in the aerospace industry to reduce the weight of materials used in aircraft, making them more fuel-efficient.

- Electronics: Glass microspheres are used in electronic components such as insulators, adhesives, and printed circuit boards.

Overall, glass microspheres offer unique properties such as low density, high strength, and chemical resistance that make them valuable in various industries and applications.

1: Binder: The application of glass microsphere in the binder can give it the advantages of weight reduction, shrinkage reduction, VOC reduction and increased filling amount.

2: Bowling ball: It can be used to control the density well. Using microspheres with different densities as fillers can better control the density and ensure the stability of the ball.

3: Deep water floating body: reduce the amount of resin used in production, thus reducing the cost; It can reduce weight; Waterproof; Easy to grind (good grinding performance); Easy processing (low viscosity, good flow performance)

4: Polyurethane injection molding: It can reduce cost, easy to polish, easy to process, reduce shrinkage, reduce warpage, and reduce weight.

5: Plugging agent: used as a plugging agent, it can reduce shrinkage and prevent cracking.

6: Artificial stone: It can be easily polished, easily processed, reduce weight, and prevent from thermal cracking (that is, its thermal insulation property has the effect of resisting thermal shock)

7: Cement: adding ceramic tile cement can reduce shrinkage and increase flow.

8: Polyester casting: used for furniture decoration, it can reduce the amount of resin used to reduce costs, easy to polish, easy to process, reduce shrinkage, reduce warpage, reduce weight, and have the effect of heat preservation, making it feel good.

9: Golf ball: (light ball) mainly refers to the effect of weight reduction.

10: Ship putty: used in ship putty can reduce resin consumption, cost, weight, shrinkage and warpage.

11: Clamping board putty: it can reduce cost, weight, shrinkage and warpage.

12: Ceramic material (lightweight): it can reduce the cost, shrink, dielectric constant and heat insulation.

13: Wall putty: It can be easily polished and reduce shrinkage.

14: Synthetic foam: It has the effect of reducing cost and weight.

15: SMC, BMC and other composite materials such as glass fiber reinforced plastic and wood plastic can reduce weight, resin consumption, cost, heat preservation, shrinkage, warpage and easy processing.

16: Application of paint:

(1) Interior and exterior wall coatings of buildings: improve the reflection, heat insulation, durability, waterproof and scrub resistance of coatings; nature

(2) Thermal insulation coating: good thermal insulation effect, increase the building area, energy conservation and environmental protection, and reduce building energy consumption.

17: Glass microspheres are used in oil and gas fields:

(1) Drilling fluid: it can be added to various drilling fluids as a density reducing agent, and its main advantages are: well reducing the density of drilling fluid; It reduces torque and friction, and does no harm to the formation. It works with leak loss reducer to reduce circulating leakage. It is easy to mix and pump. Grout replenishing can be easily mixed on site without special equipment. It has high stability, good compression resistance, and no impact on the performance of drilling and downhole equipment. Microspheric drilling fluid is single-phase and incompressible, so it can be easily used for fluid calculation and measurement while drilling. It has no effect on rheological properties. It can be recycled and reused.

(2) Cementing cement: it is used in cementing cement, and its main advantages are: it can reduce the density very well, and has good rheological property, improve the displacement speed, high and tight cementation strength, reduce leakage, reduce the waiting time, easy to mix, no special equipment, easy to pump, high cementing strength, high compressive strength, no need for multi-stage cementing.

1. The alkaline lime borosilicate ingredients of the glass microspheres make it stable and inertia for its chemical properties, which gives them safely as a filler or as an additive, without worrying Can resist other chemical corrosion other than strong alkali.

2. The perfect spherical shape gives them excellent consistency, so that after processing, it will not cause warning and contraction due to inconsistent stress.

3. The hollow glass micro -ball is a tiny ball. In the liquid, the action -like micro -rolling bearing bearing should be more liquid than the fillers of the chip, needle, or irregular shape. Decreasing the viscosity of the mixture, the performance of the model is naturally excellent; good processing performance can increase production efficiency by 10%to 20%.

4. The perfect spherical shape makes it have a small ratio of Z, so its oil absorption is low. Compared with the conventional filling material calcium carbonate, the fuel absorption rate/volume of hollow glass microspheres is much lower, and different types of products are 100 grams per 100 grams The oil absorption rate is between 7 and 40 mg, while the oil absorption rate per 100 grams of light calcium carbonate is as high as 120 to 130 mg, and the heavy calcium carbonate is as high as 50 to 60 mg. The amount of resin is reduced, and at the same time, because it can play a role in increased liquidity of the resin, the resin can only be processed as a substrate rather than the filler, which also reduces the amount of resin.

5. Due to the particle size distribution of glass microspheres, small microspheres fill the gap of large microspheres, which increases its solid content. At the same time, its volatile capacity is very low, which reduces VOC.

6. The color is white, so it has good color compatibility.

7, very low real density and strong compressive strength, resulting in its high compressive strength density ratio, which makes it in some applications that require high pressure resistance, such as squeezing, pressing, or pressurizing, or pressing, or pressing, or pressing, or pressing, or pressing, or pressing, or pressing, or pushing, or pushing, or The oil industry can not only play the role of fillers or additives that density density, but also enable it to have a good survival rate and stability in the processing process

8. The particle size is small, and it may not reduce its toughness when mixing with the resin.

9: The interior of the hollow glass microsphere is a vacuum and thin gas. There are poor density and heat conduction coefficients in two different materials. Therefore, it has the characteristics of sound insulation, heat insulation, and low heat conduction. Fill. The thermal insulation characteristics of microspheres can also be used to protect the heat shock caused by alternating changes between the products and the cold conditions of the product.

10: The closed rate is very high, the spherical shape is tight and perfect, and it is insoluble in water, so that its application in the water is also very stable, and the water will not enter the inside of the microsphere. Therefore It is insoluble in water, and its applications in water such as yachts and rowing are also extremely stable.

11: As a test shows that the fillers of hollow or low hardness will absorb and digest the impact intensity when they are impacted, which improves the impact performance of the material. Therefore, it can improve the physical and mechanical properties of plastic products. At the same time, its filling plastic can greatly increase the hardness and elastic modulus of the material, and the ability of stiffness and stress damping has also improved.

12: It can maintain its stability below 600 degrees, so it is also stable in some applications that require a slightly higher temperature.

ARTICLE SOURCE : SHANGHAIHUIJING

Glass microspheres have a very important role in production and life. The glass micro -balls are not only light quality, low heat conduction, high strength, and good chemical stability, but also have the performance of hydrocariasis on the surface, which is easy to scattered in the organic material system. So what are the main characteristics of glass microspheres?

Main features of glass microspheres

1. There is a scattering effect on visible spectral range light. The glass material is actually colorless and transparent, but because the glass ball has a scattering effect on the full visible spectral range of the spectral range, it looks white. However, when it is added to the color material, it is also scattered with the light of the material color, so it can be widely used in any material required by the appearance and color without affecting the color of the original material.

2. Lear density. The density of glass microspheres is about one -third of the density of traditional filling particles. After filling, it can greatly reduce the base weight of the product, and the large volume makes it replace a large amount of other raw materials and reduce the cost of the product.

3. It has parental oil. Weting and decentralizing hollow glass microspheres can be filled in most thermal thermoplastic resins, such as polyester, epoxy resin, polyurethane, etc.

4. High decentralization and good liquidity. Because the glass micro -ball is a tiny ball, it is more liquid than the fillers of the liquid resin than the chip, needle, or irregular shape, so the model is excellent. What’s more important is that this small micro -ball is different, so it will not produce disadvantages of inconsistent contraction rates caused by different parts of the orientation, ensuring the size of the product stable and not warpage.

5. Low water absorption. The interior of the glass microsphere is thin gas, so it has the characteristics of sound insulation and heat insulation. It is an excellent fillers for various insulation and sound insulation products. The heat insulation characteristics of glass microspheres can also be used to protect the heat shock caused by alternate changes between the products and the conditions of rapid heat and cold. The high ratio resistance, the extremely low water absorption rate allows it to be widely used in processing and production cable insulation materials.

6. Low oil absorption. The particles of the sphere determine that it has the smallest surface area and low oil absorption rate. During the use process, the amount of resin can be greatly reduced. Even if the amount of high addition is added, the viscosity will not increase much, which greatly improves the production operation conditions. Increase production efficiency by 10%to 20%.

Glass microspheres are divided into hollow glass microspheres and solid glass microspheres

1. The main application fields of solid glass microbeads are:

1. Road reflective glass beads:

Road reflective glass beads are divided into internal mixing type and surface scattering type. The internal mixing type is mixed in the paint during the production of road reflective paint, which can ensure the long-term reflection of road markings within the life period.

The surface sprinkler type is used in road marking construction to spread on the surface of the marking line to achieve an instant reflective effect. Road marking glass beads are divided into two specifications: coated and non-coated. Surface-treated coated glass beads are used in road marking construction, which can greatly improve the adhesion between the glass beads and the road marking paint. , Water resistance, enhance the reflectivity of road markings, and have self-cleaning, anti-fouling, moisture-proof and other uses.

2. Shot peening glass beads:

Shot peening glass beads Glass beads used for industrial shot peening and additives can be used on metal surfaces and mold surfaces without damaging the surface of the workpiece and improving the accuracy of the workpiece. It is used for cleaning and polishing of metal metal, plastic, jewelry, precision casting and other objects. It is a high-grade finishing material commonly used at home and abroad.

3. Grinding glass beads:

Grinding glass beads have the advantages of good chemical stability, mechanical strength and hardness, surface finish, good fluidity, low abrasion, easy industrial and mining control, etc. As abrasive materials, they are widely used in chemical materials, coatings, pigments, food, medicine and other fields.

4. Glass beads for decoration:

Glass microbeads, glass sand and colored glass microbeads for handicrafts are ideal materials for garment printing, garment heat transfer, Christmas tree surface decoration, artificial fruit, artificial flower crafts surface decoration, and hourglass quicksand manufacturing.

5. Filling:

Glass beads are also widely used as a new type of material in various fields such as medical equipment and nylon, rubber, engineering plastics, and aviation. Such as additives, enhancers and so on.

2. The main application fields of hollow glass microspheres are:

1. The color is pure white, which can be widely used in any products that have requirements on the appearance color.

2. The specific gravity is light, and the density of hollow glass microspheres is about one tenth of the density of traditional filler particles. After filling, the basis weight of the product can be greatly reduced, more production resins can be replaced and saved, and the product cost can be reduced.

3. Lipophilic, hollow glass microspheres are easy to wet and disperse, and can be filled in most thermosetting thermoplastic resins, such as polyester, epoxy resin, polyurethane, etc.

4. Good fluidity. Since hollow glass microspheres are tiny spheres, they have better fluidity in liquid resins than flake, needle or irregular fillers, so they have excellent mold filling performance. More importantly, the small microbeads are isotropic, so there is no disadvantage of inconsistent shrinkage rates in different parts due to orientation, which ensures the dimensional stability of the product and will not warp.

5. Heat and sound insulation, the hollow glass beads are thin gas inside, so it has the characteristics of sound insulation and heat insulation, and it is an excellent filler for various thermal insulation and sound insulation products. The insulating properties of hollow glass microspheres can also be used to protect products from thermal shock caused by alternating between rapid heating and rapid cooling conditions. High specific resistance and extremely low water absorption make it widely used in the production of cable insulation materials.

6. The oil absorption rate is low. The particles of the sphere determine that it has the smallest specific surface area and low oil absorption rate. During use, the amount of resin can be greatly reduced. Even under the premise of high addition amount, the viscosity will not increase a lot, which is greatly improved. The production operating conditions can be improved, and the production efficiency can be increased by 10% to 20%.

Article Source:HS glass beads

Hollow Glass Microspheres H46

How do you make glass microspheres?

1. Glass powder method

The glass powder method uses pre-prepared glass powder containing gases such as SO3 to pass through the flame at the temperature of 1100-1500℃. At this time, SO3 and other gases dissolved in the glass powder overflow from the inside of the glass due to the decrease in solubility and the change in the atmosphere of the kiln. At the same time, the glass powder becomes spherical under high temperature due to the surface tension. The spillage gas is sealed in the spherical particles to form hollow glass beads.

2. Spray granulation method

Spray granulation method is made in advance with special auxiliary reagent (boric acid, urea, ammonium pentaborate) aqueous solution of sodium silicate, and then through the nozzle to the solution injection into the spray dryer, is expected to drop after drying to get a certain particle size of powder particles, the final will be powder particle heating foam-forming hollow glass beads.

3. The droplet method

The liquid drop method adopts the same raw materials as the spray granulation method. The raw materials are 500 copies of sodium silicate (M (SiO2): M (Na2O) =2), and the same amount of 10% ammonium perborate aqueous solution is added. After mixing evenly, the hollow glass beads are sprayed into the spray drying tower.

4. Dry gel method

The alkyl salt was added to dilute hydrochloric acid and decompose with water. After gelation, the gel was dried in two stages at 60℃ and 150℃ and then crushed by a ball mill. After grading, the dried gel powder was obtained, which was foamed in a vertical electric furnace at 1280℃ to prepare hollow glass microspheres.

Applications of Hollow Glass Sphere :

Hollow glass microspheres are widely used in glass fiber reinforced plastic products, composite foam plastic, artificial marble, compound wood, sound insulation heat preservation material, atomic ash, deep-sea buoyancy, bowling, low-density cement, sealing material, lightweight, resin handicraft, the mural wall hanging frame, wall plate sandwich layer structure of lightweight packaging materials, electronic industry, absorbing material, lightweight concrete, such as emulsion explosive.

Hollow glass microspheres also provide a conductive coating. Conductive coatings of optimized thickness provide spherical particles with excellent conductivity and shielding properties while maintaining the weight savings associated with hollow, low-density materials. These conductive microbubbles are suitable for military applications, biotechnology, medical devices, electronics and other special industries.

Hollow glass beads have obvious weight reduction and sound insulation and heat preservation effect so that the products have good cracking resistance and reprocessing performance, is widely used in engineering plastics, insulation materials, rubber, buoyancy material, FRP, artificial marble, man-made agate, generation of composite materials such as wood, and the oil industry, aerospace, communications, 5 g new high-speed trains, cars, ships, in areas such as thermal insulation coatings, adhesives, vigorously promote the development of science and technology.

FROM:TRUNNANO

Improving flow properties.

Hollow glass microsphere is a tiny sphere with high ball-type rate. Its ball-bearing effect can improve its mobility and reduce the viscosity and internal stress of resin mixture. Therefore, during processing, less heat is produced in composite materials so as to prevent inadequate lubrication and partial thermal decomposition. It is more likely to extrude when molding, which can not only reduce defects in products, but also improve the production efficiency by 15% -20%.

More substitute ability for resin.

Hollow glass microspheres occupy less surface area, low oil-absorption rate, and evenly disperse in mixture. Its easy compression and integration permit high filler loadings. It significantly reduces the consumption of resins, increases the amount of filler, and effectively reduces VOC indicators, and costs as well.

Low shrinkage and warpage.

Hollow glass microspheres have the feature of isotropism and high-filling, hence the dimensional stability of the product will be very high and it will reduce the shrinkage and warpage. With an appropriate filling ratio, the toughness of the products, impact-resistance and surface hardness can be significantly improved.

More economical by volume.

The density of high-performance hollow glass microspheres is only a fraction of that of the resin. A small amount of hollow glass microspheres will be able to replace heavier materials. When considering the cost per unit volume, rather than cost per unit weight, high-performance hollow glass microspheres can significantly reduce costs.

Adjusting the density of products .

The density of hollow glass microspheres is usually 0.20 ~ 0.60g/cm3, and the density of mineral filler is generally around 2.7 ~ 4.4 g/cm3 (The data adopted is the true particle density). In order to obtain the equal size, 14 kilograms or more of talc must be used to obtain the same effect of 1 kg of hollow glass microsphere. Hence the desired ideal density can be obtained by adding appropriate proportions of hollow glass microspheres.

Good fluidity, product size, excellent stability. As a result of hollow glass microspheres are small ball, in a

liquid, moves like the miniature ball bearing, than flake, needle or irregular shape of the filler has good fluidity,

the resulting microspheres effect, to make the mixture viscosity decreased, the filling properties of the natural

good; good processing performance, can improve the production efficiency by 10% ~ 20%. Because the spherical body is

isotropic, so filled microspheres not due to alignment caused by different parts of shrinkage rate inconsistent

shortcomings, to ensure product size stability, does not warp, solve the profile, large plastic injection molding

products processing long-standing deformation problem.