Glass microspheres are divided into hollow glass microspheres and solid glass microspheres

1. The main application fields of solid glass microbeads are:

1. Road reflective glass beads:

Road reflective glass beads are divided into internal mixing type and surface scattering type. The internal mixing type is mixed in the paint during the production of road reflective paint, which can ensure the long-term reflection of road markings within the life period.

The surface sprinkler type is used in road marking construction to spread on the surface of the marking line to achieve an instant reflective effect. Road marking glass beads are divided into two specifications: coated and non-coated. Surface-treated coated glass beads are used in road marking construction, which can greatly improve the adhesion between the glass beads and the road marking paint. , Water resistance, enhance the reflectivity of road markings, and have self-cleaning, anti-fouling, moisture-proof and other uses.

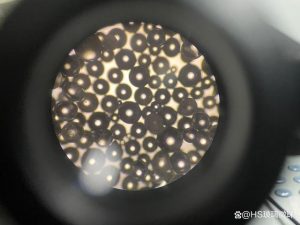

2. Shot peening glass beads:

Shot peening glass beads Glass beads used for industrial shot peening and additives can be used on metal surfaces and mold surfaces without damaging the surface of the workpiece and improving the accuracy of the workpiece. It is used for cleaning and polishing of metal metal, plastic, jewelry, precision casting and other objects. It is a high-grade finishing material commonly used at home and abroad.

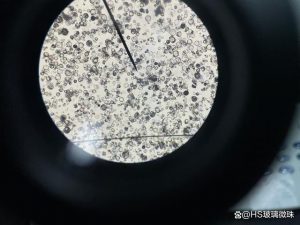

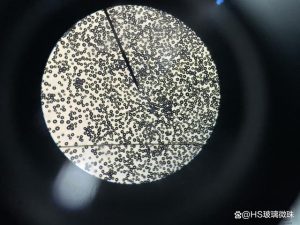

3. Grinding glass beads:

Grinding glass beads have the advantages of good chemical stability, mechanical strength and hardness, surface finish, good fluidity, low abrasion, easy industrial and mining control, etc. As abrasive materials, they are widely used in chemical materials, coatings, pigments, food, medicine and other fields.

4. Glass beads for decoration:

Glass microbeads, glass sand and colored glass microbeads for handicrafts are ideal materials for garment printing, garment heat transfer, Christmas tree surface decoration, artificial fruit, artificial flower crafts surface decoration, and hourglass quicksand manufacturing.

5. Filling:

Glass beads are also widely used as a new type of material in various fields such as medical equipment and nylon, rubber, engineering plastics, and aviation. Such as additives, enhancers and so on.

2. The main application fields of hollow glass microspheres are:

1. The color is pure white, which can be widely used in any products that have requirements on the appearance color.

2. The specific gravity is light, and the density of hollow glass microspheres is about one tenth of the density of traditional filler particles. After filling, the basis weight of the product can be greatly reduced, more production resins can be replaced and saved, and the product cost can be reduced.

3. Lipophilic, hollow glass microspheres are easy to wet and disperse, and can be filled in most thermosetting thermoplastic resins, such as polyester, epoxy resin, polyurethane, etc.

4. Good fluidity. Since hollow glass microspheres are tiny spheres, they have better fluidity in liquid resins than flake, needle or irregular fillers, so they have excellent mold filling performance. More importantly, the small microbeads are isotropic, so there is no disadvantage of inconsistent shrinkage rates in different parts due to orientation, which ensures the dimensional stability of the product and will not warp.

5. Heat and sound insulation, the hollow glass beads are thin gas inside, so it has the characteristics of sound insulation and heat insulation, and it is an excellent filler for various thermal insulation and sound insulation products. The insulating properties of hollow glass microspheres can also be used to protect products from thermal shock caused by alternating between rapid heating and rapid cooling conditions. High specific resistance and extremely low water absorption make it widely used in the production of cable insulation materials.

6. The oil absorption rate is low. The particles of the sphere determine that it has the smallest specific surface area and low oil absorption rate. During use, the amount of resin can be greatly reduced. Even under the premise of high addition amount, the viscosity will not increase a lot, which is greatly improved. The production operating conditions can be improved, and the production efficiency can be increased by 10% to 20%.

Article Source:HS glass beads