How to Reduce Density of Rubber Vacuum Glass Bead Foaming Agent Special for Rubber Weight Reduction

Why rubber has high density;

The density of the rubber without filler is 0.9g/cm, but the rubber needs to add inorganic filler because of its strength, temperature resistance, shrinkage resistance, cost reduction and other characteristics. The filler density is generally 2.5-3.6, which will greatly increase the weight, leading to the rubber density exceeding the standard.

Inorganic filler powder

Methods for reducing the density of rubber;

The vacuum glass beads are added to the rubber. The density of the vacuum glass beads is 0.23-0.28g/cm, 3-5 times lighter than the rubber. The compressive strength is 35-42MPA. It has high strength and does not crush. It can be filled into rubber and other materials to effectively reduce the weight to meet the density standard.

Vacuum glass beads are often used to replace foaming agents in rubber soles. Because of their high strength, strong weather resistance, high hardness, and strong aging resistance, vacuum glass beads will not collapse for a long time after they are made into soles, delaying their service life.

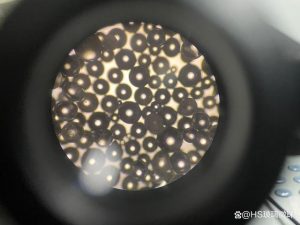

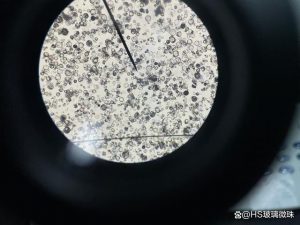

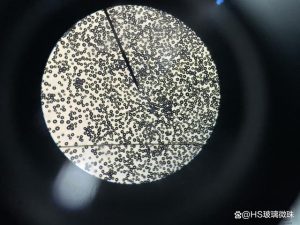

Real shot of vacuum glass bead

Why vacuum glass beads can reduce weight;

Vacuum glass bead is a kind of bubble type ultra-fine inorganic powder. The microscopic view is closed spherical hollow particles. The glass bead is filled into the resin, plastic and rubber to achieve foaming effect and effectively reduce the product density.

Vacuum glass bead morphology;

Vacuum glass bead is a kind of low density inorganic white solid powder, which is made by chemical method. It presents spherical vacuum powder under a microscope. The density of conventional products is generally 0.15-0.8g/cm, and it is often used for thermal insulation coatings, plastic foaming, rubber weight reduction, etc.

Plastic anti warping glass beads;

The vacuum glass bead can prevent warping, reduce shrinkage, resist high temperature, fire and other characteristics after being added into the plastic. The recommended usage is 7-20%, which is adjusted according to the product characteristics.

Vacuum glass beads are widely used;

It can be used for reflective coatings, silica gel pads, silica gel products, resins, thermal insulation coatings, thermal insulation coatings, thermal insulation layers, thermal insulation paints, thermal insulation intermediate coatings, rubber soles, rubber pads, yoga mats, reflective coatings, thermal insulation coatings, printing coatings, plastic products, plastic plates, wood plastics, man-made boards and other products with wide applications and strong chemical stability.

FAQ;

Q: The role of plastic filled hollow glass beads;

Answer: Hollow glass beads have the effects of low density, insulation, light weight and heat insulation. Adding them to plastics can reduce the weight. Increase liquidity.

Q: The effect of insulating glass beads used in thermal insulation coatings;

Answer: After insulating glass beads are added to the thermal insulation coating, the thermal insulation effect of the coating can be greatly enhanced.

Q: What is added to rubber to reduce density;

Answer: The use of vacuum glass beads can effectively reduce the density, increase the volume and enhance the overall performance of rubber.

Q: What is the thermal conductivity of the vacuum glass bead;

Answer: The special thermal conductivity of nano water-based thermal insulation coating is 0.03, which effectively reduces the performance of 15-25 ℃.