1. The alkaline lime borosilicate ingredients of the glass microspheres make it stable and inertia for its chemical properties, which gives them safely as a filler or as an additive, without worrying Can resist other chemical corrosion other than strong alkali.

2. The perfect spherical shape gives them excellent consistency, so that after processing, it will not cause warning and contraction due to inconsistent stress.

3. The hollow glass micro -ball is a tiny ball. In the liquid, the action -like micro -rolling bearing bearing should be more liquid than the fillers of the chip, needle, or irregular shape. Decreasing the viscosity of the mixture, the performance of the model is naturally excellent; good processing performance can increase production efficiency by 10%to 20%.

4. The perfect spherical shape makes it have a small ratio of Z, so its oil absorption is low. Compared with the conventional filling material calcium carbonate, the fuel absorption rate/volume of hollow glass microspheres is much lower, and different types of products are 100 grams per 100 grams The oil absorption rate is between 7 and 40 mg, while the oil absorption rate per 100 grams of light calcium carbonate is as high as 120 to 130 mg, and the heavy calcium carbonate is as high as 50 to 60 mg. The amount of resin is reduced, and at the same time, because it can play a role in increased liquidity of the resin, the resin can only be processed as a substrate rather than the filler, which also reduces the amount of resin.

5. Due to the particle size distribution of glass microspheres, small microspheres fill the gap of large microspheres, which increases its solid content. At the same time, its volatile capacity is very low, which reduces VOC.

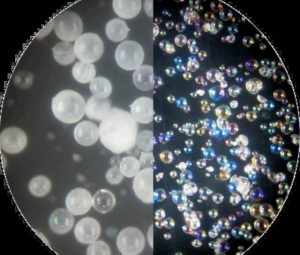

6. The color is white, so it has good color compatibility.

7, very low real density and strong compressive strength, resulting in its high compressive strength density ratio, which makes it in some applications that require high pressure resistance, such as squeezing, pressing, or pressurizing, or pressing, or pressing, or pressing, or pressing, or pressing, or pressing, or pressing, or pushing, or pushing, or The oil industry can not only play the role of fillers or additives that density density, but also enable it to have a good survival rate and stability in the processing process

8. The particle size is small, and it may not reduce its toughness when mixing with the resin.

9: The interior of the hollow glass microsphere is a vacuum and thin gas. There are poor density and heat conduction coefficients in two different materials. Therefore, it has the characteristics of sound insulation, heat insulation, and low heat conduction. Fill. The thermal insulation characteristics of microspheres can also be used to protect the heat shock caused by alternating changes between the products and the cold conditions of the product.

10: The closed rate is very high, the spherical shape is tight and perfect, and it is insoluble in water, so that its application in the water is also very stable, and the water will not enter the inside of the microsphere. Therefore It is insoluble in water, and its applications in water such as yachts and rowing are also extremely stable.

11: As a test shows that the fillers of hollow or low hardness will absorb and digest the impact intensity when they are impacted, which improves the impact performance of the material. Therefore, it can improve the physical and mechanical properties of plastic products. At the same time, its filling plastic can greatly increase the hardness and elastic modulus of the material, and the ability of stiffness and stress damping has also improved.

12: It can maintain its stability below 600 degrees, so it is also stable in some applications that require a slightly higher temperature.

ARTICLE SOURCE : SHANGHAIHUIJING