Summary of Process

Feed material may be glass frit, other dry particles or solutions containing the forming components

Compositions are typically soda lime silicates, sodium borosilicates, etc.

Feed must contain a blowing agent

A blowing agent is a material that decomposes and releases gas at elevated temperature

Commonly sulfur-containing compounds

Feed material is introduced into a flame at elevated temperatures (~1100-1400°C)

Gas released by the decomposition of the blowing agent causes particles or droplets to expand to hollow glass microsphere.

SRNL has developed an experimental apparatus for forming HGMs based on this technique.

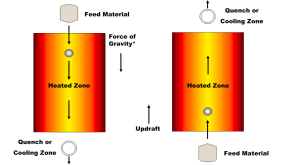

Particles may enter the flame by:

Falling downward due to the force of gravity

An updraft may be used to control the residence time in the flame

Particles have a short residence time in the heated zone

Conducive to HGMs with smaller diameters

Ascending upward by a gaseous stream

Residence time in heated zone is longer

HGMs with larger diameters are produced

For More Information:

Up Flow

Sodium Silicate Particles

US Pat. 2,978,339 F. Veatch Emerson & Cuming

Spray Drying Sodium Silicate Solutions

US Pat. 3,669,050 C. Henderson Emerson & Cuming

Glass Particles

US Pat. 4,661,137 P. Garnier Saint Gobain

US Pat. 5,256,180 P. Garnier Saint Gobain

Down Flow

Clay Particles

US Pat. 2,676,892 J.D. McLaughlin Ferro Corp

Glass Particles

US Pat. 3,365,315 W.R. Beck 3M Co.

US Pat. 4,391,646 P.A. Howell 3M Co.

US Pat. 4,767,726 H.J. Marshall 3M Co.

US Pat. 6,254,981 R.B. Castle 3M Co

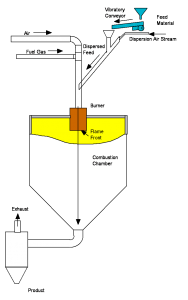

Feed is introduced at the bottom of the furnace

Feed is introduced at the bottom of the furnace

A hot, gaseous stream carries the feed upward

Residence time within the hot zone of the furnace is a function of:

Particle mass

Upward velocity of the gas stream

Residence time is critical – just enough time to form a “tough outer skin”

Hollow sphere must then be removed at the point of maximum expansion and moved through regions of progressively diminishing temperatures

“Outer skin” cools and solidifies providing mechanical strength

The cyclone separates the HGMs from the gases

HGMs are produced with diameters of ~10 – 350 μm

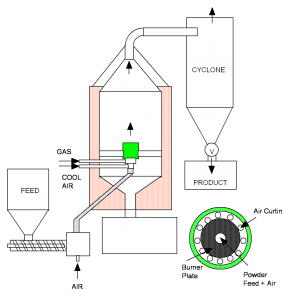

Feed is introduced at the top of the heating chamber by a vibratory funnel

A “fluidizing agent” may be added to the particles to improve dispersion

The particles are transported to the flame by a carrier gas

Carrier gas further disperses particles

Particles fall though the flame front where fusion occurs

HGMs are cooled and separated from the gas mixture by a cyclone

HGMs are produced with diameters less than 125 μm