The impact of micro -pearl powder in the plating fluid on chemical silver plating

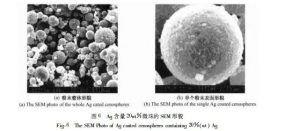

In order to eliminate the single -quality silver in the middle of the powder, the amount of plating powder is used to reduce the silver content in the plating powder. Figure 6 shows the overall powder of 20%of the AG content and the surface shape of a single powder. Compared with Figure 6 (a) and 4, it can be seen that with the increase of the amount of powder coverage, the single silver from the pink decrease significantly. This is because the larger the loading capacity, the larger the surface area, the more the core of the silver nucleus, which reduces the appearance of silver single. From Figure 6 (b), it can be seen that except for a few silver particles on the surface of the powder, the size is basically about 50 nm, which is related to the increase in the surface area of the powder and the increase in the area of silver -shaped nuclei, which is related to the increase in the number of cores. Because in the same amount of silver analysis, the larger the number of silver cores, the shorter the core of the core, and the result is reduced to the silver particle size plated on the surface.

in conclusion

The chemical silver plating of hollow glass microspheres is prepared to prepare the hollow glass micro beaded powder with a dense and continuous coating layer. The thickness of the coating layer is about 50 nm. Energy characteristics. At the same time, the effect of chemical silver -plated process parameters on the silver -plated silver plating of hollow glass, and found that:

1. By increasing the content of NAOH in the plating solution. Increasing the P field value of the plating liquid can increase the amount of silver analysis in the plating solution, the coating of the micro -bead surface is more dense and continuous, but there is a single -quality silver with free states;

2. Stabilizer can improve the self -decomposition of the plating fluid, but it has little effect on the uniformity and thickness of the coating of the microfin surface. On the contrary, when the amount of stabilizer is too large, it will also cause the unevenness and denseness of the surface covering layer;

3. By adjusting the loading capacity of the hollow glass microsphere, it can adjust the particle size of the surface of the silver particles, control the thickness of the silver -plated layer, and increase the loading capacity at the same time, which can also reduce the phenomenon of self -decomposition.