Artificial marble and onyx products in the application of hollow glass microspheres larger purpose is artificial marble. In the US, there are a lot of manufacturers are using this filler, it has the following advantages:

1.Improve impact resistance, properly formulated products manufactured its performance is higher than the requirements for artificial marble Association.

2.Continuous improvement of texture and color layout, making the product more attractive, magnificent.

3.Reduce the curing time, the mold has a faster turnover rate.

4.Improved impact strength, improved anti-cracking ability, reduce breakage of the product.

5.Improved machinability, reducing deburring, cutting, drilling and grinding of empty time.

6.Post-processing tools to reduce wear.

7.Improving the light color color performance, while reducing the amount of TiO2. (although sometimes mixed with some darker colors)

8.Light weight, to make it easier in handling and installation process, but also reduces the cost of transportation. Benefits listed above 3-8 can significantly reduce costs.

Currently, the use of microwave radar, infrared, radar or other electromagnetic radar and acoustic detection system shield absorbing material has been widespread concern in the military field. Near-infrared reflective material can be used in aviation, aerospace, construction materials, vehicles, weapons and other fields. Hollow glass bubble powder density is small, the metal surface after its treatment, can be substituted denser metal powder or electromagnetic wave absorption preparation screen material used.

Posted by admin on June 20, 2016 at 2:07 am under Hollow Glass Microspheres.

Comments Off on Artificial marble and onyx products in the application of hollow glass microspheres.

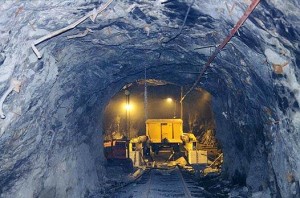

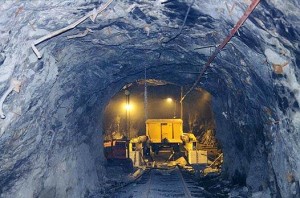

Glass Bubbles are, as the name suggests, hollow bubbles of glass perfect for creating reliable explosive sensation.

With glass bubbles you can be confidant you will get more “bang for your buck.”

From:3M

Posted by admin on June 13, 2016 at 6:32 am under glass bubble.

Comments Off on Glass Bubbles for Mining.

High-performance glass bubble & hollow glass microsphere T32 is a kind of ultra-lightweight inorganic non-metallic material with hollow structure, and it is a versatile and high-performance new lightweight material developed in recent years. It will be the new composite materials at twenty-first century. Its true density is 0.15-0.60g/cm3 with 2-120m in diameter. It owns features with light weight, large bulky, low thermal conductivity, high compressive strength, smoothly mobility etc.

Posted by admin on June 7, 2016 at 6:03 am under Hollow Glass Microspheres.

Comments Off on Hollow glass microspheres T32.

Glass bubble as a carrier of a catalyst, with a large surface area, pore size can be translucent in the appropriate range, compared with the organic carrier, it is not subject to microbial invasion, high intensity, can improve the carrier properties, get better catalytic effect. Its development environment for building regulation has used material is a new creation, the bedroom can improve environmental conditions, the environment as a result of the removal of fumes, causing mildew odor, odor, adjust the indoor temperature, humidity, cold, hot, identify environmentally harmful gases such as monitoring of the ecological environment protection and regulation are important. Due to the presence of a large number of micro beads having adsorption characteristics, and can be applied to sensor technology and bio-engineering.

Hollow glass bubble is a new multi-purpose powder material, a lightweight, good mobility, chemical stability, and low cost, as the space age materials. But hollow glass bubble absorbing powder itself does not have the capacity, the need for its surface modification.

Posted by admin on June 4, 2016 at 3:06 am under glass bubble.

Comments Off on Delve into Hollow glass microspheres.

In recent years, with the radar, the development of microwave communication technology, increasingly complex electromagnetic environment of space, in order to reduce and mitigate electromagnetic radiation on the social environment and human health hazards, the application of electromagnetic wave absorbing materials increasingly widespread, especially for high-frequency, ultra-high frequency microwave absorbing material needs, and promote the research and development of electromagnetic wave absorbing materials. Absorbing material by molding and the carrying capacity of the coating type and structure can be divided into two types, which is coated absorbing materials in its process is simple, inexpensive and widely accepted, widely used in various electronic products, equipment, electromagnetic radiation protection system. However, the use and development at home and abroad are still absorbing material density and high cost, the scope of application subject to certain restrictions.

In recent years, due to man-made glass bubble consume more energy, people turn to get hollow glass bubble fly ash from thermal power plants. In our current carbon emissions in fly ash, hollow glass bubble is generally about 50%, ash hollow glass bubble emerging as a versatile material, because of its fine particles, hollow, lightweight, high temperature insulation , insulation, wear-resistant, alkali, chemical stability and other properties, has been widely used in building materials, plastics, rubber, paint, chemical, metallurgy, marine and aerospace and other fields.

Posted by admin on May 31, 2016 at 2:52 am under glass bubble.

Comments Off on Surface Modification on Hollow Glass Microspheres.

Glass Bubbles for Defense

Engineered additives create lightweight, high-performance parts.

Save Fuel with Lighter Weight Parts

FROM:3M

Posted by admin on May 27, 2016 at 2:23 am under glass bubble.

Comments Off on Glass Bubbles for Defense.

High-performance glass bubble & hollow glass microsphere T20 is a kind of ultra-lightweight inorganic non-metallic material with hollow structure, and it is a versatile and high-performance new lightweight material developed in recent years. It will be the new composite materials at twenty-first century. Its true density is 0.15-0.60g/cm3 with 2-120m in diameter. It owns features with light weight, large bulky, low thermal conductivity, high compressive strength, smoothly mobility etc.

Posted by admin on May 23, 2016 at 2:17 am under glass bubble.

Comments Off on Hollow glass microspheres T20.

The range of applications in which coated microspheres and microparticles can be used to enhance current composites, or provide new solutions, is extremely diverse and the size, density, surface chemistry and functionality required by end users tend to be application specific. There is significant scope, therefore, for the development of a wide range of new materials to meet these diverse market opportunities.

Glass Microspheres are also used in composites to fill polymer resins for specific characteristics such as weight, sandability and sealing surfaces. When making large forms such as boat hulls for example, shapers seal the eps foam blanks with epoxy and lightweight microballoons to create an impermeable and easily sanded surface upon which fiberglass laminates are applied.

Posted by admin on May 16, 2016 at 2:25 am under Hollow Glass Microspheres.

Comments Off on Applications of Hollow glass microspheres.

Liver cancer is a malignant tumor, the use of chemotherapy and radiation therapy are not satisfied with the results. Taipei Veterans General Hospital cancer have the new law, after 41 patient radioactive substance injected into the Y-90 glass bubble, of which about 90% in six months or longer to ease conditions worsen, this body radiotherapy for patients to bring a ray of hope.

Taipei Veterans General Hospital physician Li Runchuan radiation Department said today that the body radiotherapy using Y-90 glass bubble, and every single microsphere diameter of only 1/3 of the hair, by the medical staff through angiography accurate positioning of the number millions of stars within microspheres injected into the arteries near the cancer lesion, the next two weeks, the microspheres can be close to the average of 0.25 cm, radiation emit high levels of β, kill cancer cells.

Hollow glass bubble spherical shell phase and gas phase. In the heat transfer process, when faced hollow glassbubble, only a small portion of the heat conduction through the glass bubble, while most of the heat is bypassed glass bubble, due to the glass bubble of low thermal conductivity, and the heat transfer path in the coating becomes long and complicated, resulting in heat transfer performance, according to the law and the minimum thermal resistance than the equivalent thermal conductivity equal rules, as long as the composite coating unit body and overall have equal than the equivalent resistance, regardless of the size scale unit body, when considering only the thermal conductivity, which means the whole body and the equivalent thermal conductivity equal.

Calculation of equivalent thermal conductivity of the composite coating, and comes down to the same ratio to calculate the equivalent resistance of the cell body of the equivalent thermal conductivity can be seen.

Posted by admin on May 11, 2016 at 6:12 am under glass bubble.

Comments Off on Glass bubble on the application in medical.

Hollow glass bubble fifties and sixties of the 20th century developed a particulate material, thin-walled borosilicate material from sodium made by a special process, closed the tiny sphere, the sphere inside the parcel certain amount of gas, it has low-density, high-low thermal conductivity, low oil absorption, high temperature resistance, dielectric strength, good thermal stability, corrosion resistance, controllable particle size and chemical composition and so on. With the development of science and technology as well as industrial mass production of hollow glass bubble achieve low hollow glass bubble material prices, variety, size increasing, can be widely used in building materials, plastics, rubber, paint, metallurgy, marine and aerospace and other fields. The main expand about this point in insulation performance.

In addition there is a 69-year-old women with colorectal cancer metastasis to the liver, cut off the right side of the large intestine after surgery, six months ago to deal with the remnants of the body radiation therapy of cancer, six weeks later, four malignant tumors was significantly reduced, and necrosis, and later liver left lobe of the new long a malignant tumor, use thermal radiofrequency treatment, and did not present any recurrence of tumor necrosis.

There is a 63-year-old women with ovarian cancer metastasis to the liver and pelvis after failure of chemotherapy, twice injected Y-90 glass bubble, until the volume is reduced and the reduced number of cancer two after surgery surgery to remove the current ongoing chemotherapy observation.

Posted by admin on May 7, 2016 at 6:45 am under glass bubble.

Comments Off on Glass bubble insulation coatings research.