product information:

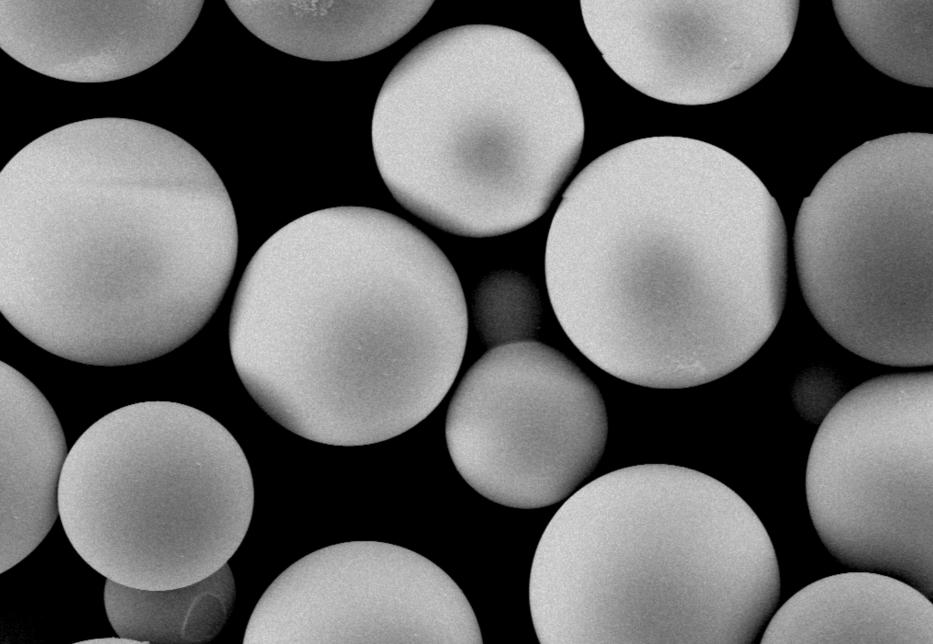

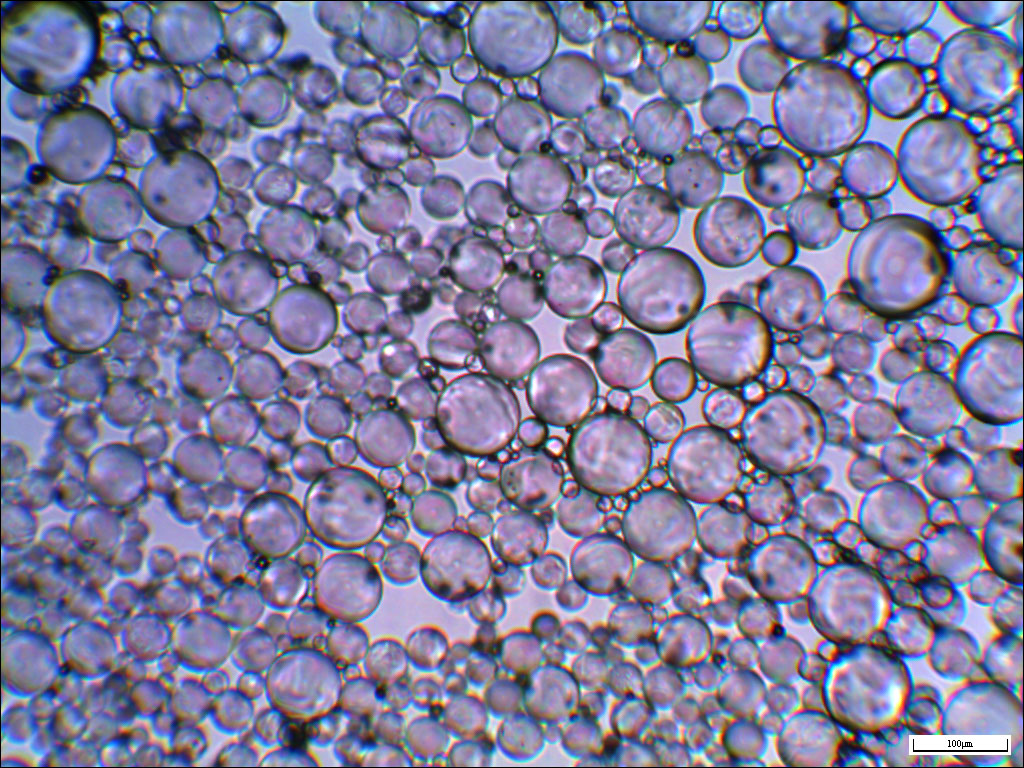

CAS No. 65997-17-3

Other Names: glass bubbles

Place of Origin: Anhui, China (Mainland)

Grade Standard: Industrial Grade

Purity: Borosilicate Glass: 97 ~100%

Appearance: white

Application: filling

Brand Name: SINOSTEEL

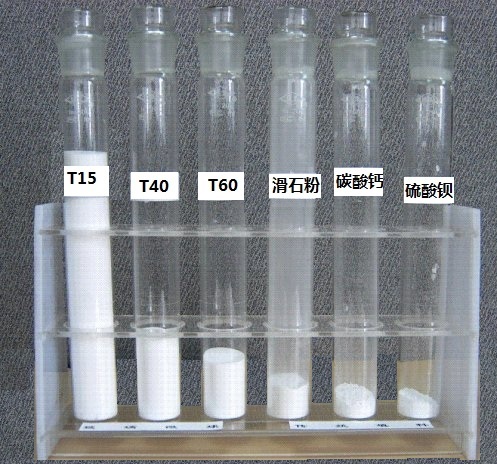

Model Number: T25/T32/T40/T46/T60

Color: white

Materials: Soda Lime Borosilicate Glass

True Density: 0.25~0.60g/cm3

Pressure Resistance: 5~60Mpa

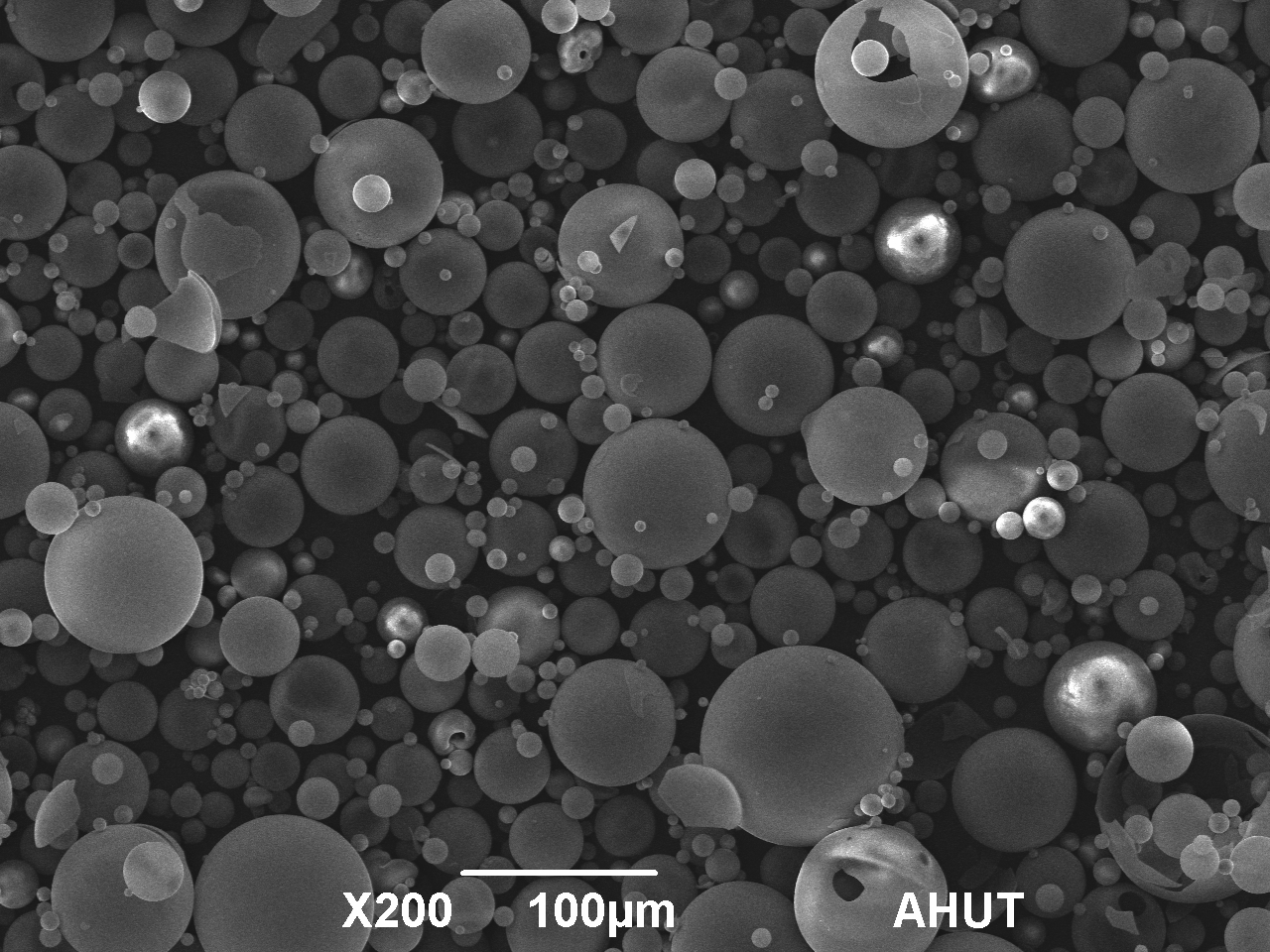

Particle Size: 2~110um

Thermal conductivity: 0.03~0.06w/m.k

Floating Rate: >94%

Melting Point: 625°C

Detailed Product Description

hollow glass microspheres can improve flow properties and more economical.

Applications

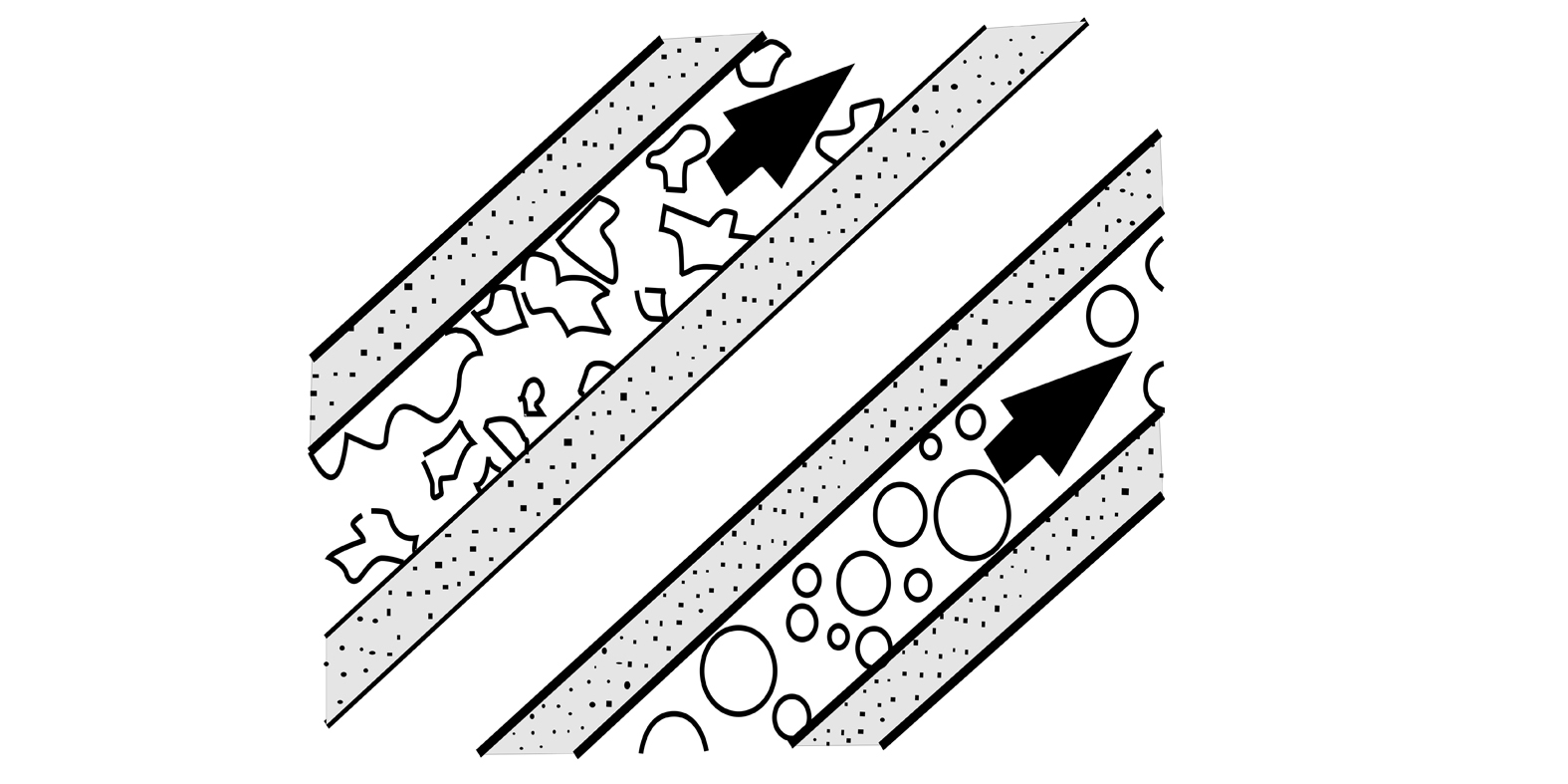

Thermal insulation coating, putty, plastic casting polyester, frp, SMC, radome, synthetic foam, adhesives, printed cir-

cuitboard substrate, RTM,bowling, fan blades, & caulking materials, emulsion explosives, golf, sealant, pipeline insul-

ation materials, artificial marble, PVC foam, low density oil drilling, light cement, and other deepsea buoy etc. Appl-

ication of Glass microspheres in plastic, rubber etc.

Hollow glass microspheres are used as filler of ultra-high molecular polyethylene. It is not only used as solid lubric-

ant in process, but can modify the comprehensive mechanical properties of the ultra-high molecular polyethylene to imp-

rove its strength and abrasion resistance. Nylon 6 with the addition of hollow glass microspheres has a higher tensile

strength, impact strength, hardness and other improved mechanical properties and can prevent the material aging caused

by the light and heat. With the increase of glass microspheres content, the Martin heat-resistant temperature of mater-

ials rises. It can used in the production of bearings, cameras, furniture and its accessories.

Hollow glass microspheres are added into rigid PVC to manufacture profiled materials, pipes and plates. These materials

have good stability in dimension, then their the rigidity, heat resistance, productivity will be improved; Filled into

ABS,this can improve the size stability of material, reduce shrinkage, improve the compressive strength and flexural

modulus, and improve the performance of the surface paint. So it can be widely used in production of TV cabinet, autom-

otive plastic parts, audio equipments, household appliances; Filled into epoxy resin,it can reduce the material’s visc-

osity and improve the mechanical properties. So it can be used in production of composite foam plastic, deepsea subma-

rine, lifeboat, etc.; Filled into unsaturated polyester. It decreases the shrinkage and water absorption of materials,

increases its wear resistance. Meanwhile, less space is produced when laminated and coated. So it can be applied in pr-

oduction of glass-steel products, polishing wheels, tools, etc.; Rubber with hollow glass microsphere is a kind of good

highpressure, wide-band and sound-absorbed material. The target body made of the rubber, has many practical advantages,

such as easily producing the zero buoyancy of the target body, and thus it is suitable for making drag target; Its good

flexibility can make target body easy folding and deploying.