Application of hollow glass microspheres in the synthetic foam.

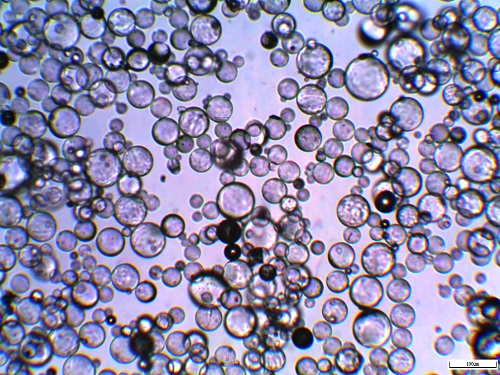

Appearance: White fine powder

Particle shape: Hollow sphere

Composition: Soda lime borosilicate quality

True density: 0.20-0.60g/cc

Average particle size: about 20-120um

Compressive strength: about 4-69MPa

Thermal conductivity: 0.03-0.06w/m.k

| Type | True Density | Crush Strength (Psi) | Crush Strength (MPa) | Particle Size(μm) | Application Suggestion | ||

| (g/cm³) | Minimum Fractional Survival≥80% | Minimum Fractional Survival≥80% | D10≤ | D50≤ | D90≤ | ||

| GS20 | 0.18~0.22 | 500 | 3.5 | 35 | 65 | 120 | Good hydrophilicity,suitable for oil drilling fields, composite materials and coatings etc. |

| GS25 | 0.23~0.27 | 750 | 5 | 30 | 60 | 115 | Good hydrophilicity,suitable for oil drilling fields, composite materials and coatings etc. |

| GS32 | 0.30~0.34 | 2000 | 14 | 25 | 55 | 105 | Good hydrophilicity,suitable for oil drilling fields, composite materials and coatings etc. |

| GS38Hs | 0.36~0.40 | 5500 | 38 | 22 | 40 | 70 | Good hydrophilicity,suitable for oil drilling fields, composite materials and coatings etc. |

| GS40 | 0.38~0.42 | 4000 | 28 | 25 | 50 | 90 | Good hydrophilicity,suitable for oil drilling fields, composite materials and coatings etc. |

| GS46 | 0.44~0.48 | 6000 | 41 | 25 | 50 | 90 | Good hydrophilicity,suitable for oil drilling fields, composite materials and coatings etc. |

| GS60 | 0.57~0.63 | 8000 | 55 | 25 | 50 | 85 | Good hydrophilicity,suitable for oil drilling fields, composite materials and coatings etc. |

Application of hollow glass microspheres in the synthetic foam board

The composite material with hollow glass microspheres and resin is commonly referred as synthetic foam board, its main characteristics is low density. With high mechanical properties, it is a wide set of multifunctional composite materials for vibration damping, insulation, fire prevention. Now it is mainly used in manufacturing of aircraft, spacecraft, and ship etc. The synthetic foam with addition of hollow glass microspheres has not only the porous structure, but also makes core materials own low moisture absorption and high compressive strength due to its closed cell structure.

High-performance glass bubble & hollow glass microsphere GS20 is a kind of ultra-lightweight inorganic non-metallic material with hollow structure, and it is a versatile and high-performance new lightweight material developed in recent years. It will be the new composite materials at twenty-firs...

Learn More>>High-performance glass bubble & hollow glass microsphere GS25 is a kind of ultra-lightweight inorganic non-metallic material with hollow structure, and it is a versatile and high-performance new lightweight material developed in recent years. It will be the new composite materials at twenty-firs...

Learn More>>High-performance glass bubble & hollow glass microsphere GS32 is a kind of ultra-lightweight inorganic non-metallic material with hollow structure, and it is a versatile and high-performance new lightweight material developed in recent years. It will be the new composite materials at twenty-firs...

Learn More>>Hollow glass microspheres occupy less surface area, low oil—absorption rate, and evenly disperse in mixture. Its easy compression and integration permit high filler loadings. It significantly reduces the consumption of resins, increases the amount of filler, and effectively reduces VOC indicators,...

Learn More>>