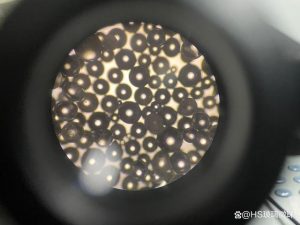

Glass microsphere has the advantages of light weight, low thermal conductivity, non-toxic, incombustible, good chemical stability and high dispersion. These advantages can be reflected in the finished products after molding. The final product is light in weight, easy to install, and especially suitable for manufacturing products requiring buoyancy.

Hollow glass beads can be used in many material fields to improve or improve the water resistance, compressive strength, shrinkage and impact strength of materials. Low density, can make lighter parts; The porosity and specific surface area are low, and the bead absorption resin is less, so the viscosity is not high even if the amount of filling is high; It is chemically stable and inert; Good anti-cracking performance, and the final product is easy to be post-processed, such as drilling, cutting and polishing, which is another advantage that hollow glass beads are easy to be damaged.

Because, like the shock absorber, the compressive strength and impact strength of the product are also improved.

Because the hollow glass bead is destroyed prior to the resin matrix, the impact degree of the product is reduced.

It is an advantage. On the one hand, it can reduce

Application of glass beads in synthetic foam

Glass bead resin composite is usually called synthetic foam. The main feature of this composite material is its low density. It is a multifunctional composite material with wide mechanical properties and a combination of vibration reduction, insulation and fire prevention.

2 Application of glass beads in plastics and rubber

In the plastic industry, glass bead is an inorganic powder filler developed in recent years, with high filling capacity. The plastic filled with it has excellent rheological processing properties, uniform shrinkage, and increased impact resistance. Glass bead is used for filling UHMWPE material, which not only acts as a solid lubricant to improve processing fluidity, but also modifies the comprehensive mechanical properties of UHMWPE material to improve its strength and wear resistance

The tensile strength, impact strength, hardness and other mechanical properties of nylon 6 with glass beads are improved, and the material aging caused by light and heat can be prevented. With the increase of glass bead content, the Martin heat resistance temperature of the material increases.

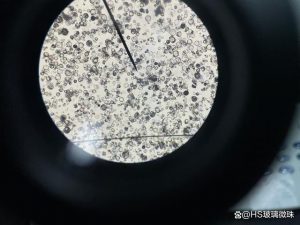

Application of glass bead in spacer material of liquid crystal display (LCD)

The spacer material of liquid crystal display is the focus of research at home and abroad, which is also one of the more promising applications of glass beads [7]. At present, LCD spacer materials often use various organic particles, and also use ground optical fibers. These materials have different degrees of shortcomings

Application of glass bead in explosives

The introduction of hollow glass beads into emulsion explosives overcomes the above shortcomings, greatly improves the detonation performance of explosives and significantly improves the storage stability

5 Application in cement products

The density of hollow microsphere is low and it is not easy to absorb water. It can reduce the density of grouting cement by adding it alone or together with expansion additives

6 Application in coatings

The glass bead is applied to the coating, and the solar heat reflection and thermal insulation coating prepared has high solar heat reflection and high radiation performance, which improves the thermal insulation performance of the coating, and is used in reflective pavement and decoration and beauty joints

7 Application in medical field

Coupling treatment of hollow glass microspheres and electroless nickel plating on the surface of hollow glass microspheres

After sex, it has a promising prospect in medical immunoassay technology.

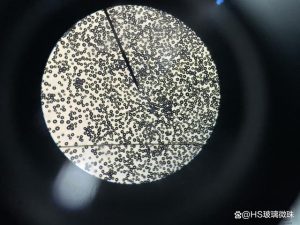

Application of modified glass beads in electromagnetic shielding and microwave absorption

Glass beads are widely used in building materials, plastics, rubber, coatings, chemistry, metallurgy, navigation, aerospace and other fields, and have irreplaceable important applications. The modified hollow microspheres have electrical and magnetic properties, which can be used in the fields of microwave absorption or electromagnetic shielding to prepare functional materials and broaden its application range. Due to the high energy consumption of artificial glass beads, the cost of glass beads obtained from fly ash can be greatly reduced, so the bead filler will have a good development prospect. At present, the utilization of fly ash hollow microsphere in China is still at the initial stage, and the utilization rate and utilization level need to be developed. As a new multi-functional material, its application prospect will be better and better.