We will take a closer look at how the unique morphology of Glass Bubbles translates to benefits in modern composite systems. We will also explore the latest in Glass Bubbles technology for composites systems.

What are Glass Bubbles?

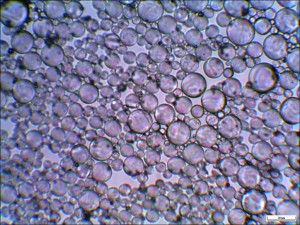

Glass Bubbles are tiny, hollow glass microspheres. They appear as a white free-flowing powder and are made from a water-resistant and chemically stabile soda-lime-borosilicate glass. Originally developed by 3M in the 1960s, they can nowadays be found almost everywhere: from the deep seas to the stratosphere, from specialist industrial applications to consumer goods. Cars, airplanes, bowling balls, fishing line, snowboards, deck chairs, and so on, all make use of the unique properties of Glass Bubbles.

The composites sector recognised early on that Glass Bubbles have an exceptional ability to reduce the weight of composite parts. Compared to conventional fillers such as talc or calcium carbonate, the density of Glass Bubbles can be 20 times lower (depending on the grade). Glass Bubbles have since become ubiquitous in resin systems including polyesters, polyurethanes, and epoxies.

Glass Bubbles are hollow glass microspheres that behave like free-flowing powders. The automotive industry has embraced these materials for their unique ability to lightweight parts as well as add other benefits.

The automotive industry in particular embraced Glass Bubble technology as lighter parts translate to improved fuel economy. In cars and trucks, Glass Bubbles can be found in composite parts such as exterior body panels, roofs, headlight reflectors, wind deflectors, fenders, floorboards, access doors, and internal panels such as engine housings and spare tire wells.

While Glass Bubbles are best known for their ability to reduce the weight of parts, this is far from their only feature. Modern applications in composites rely on the ability of Glass Bubbles to improve processing and to enhance the properties of the final composite parts. Processing improvements generally refer to the ability to produce parts at increased production speed and with greater ease. Property enhancements refer to complementary functionalities brought on by the Glass Bubbles. These can be extremely diverse, ranging from mechanical properties (stiffening) to fire-retardant properties, acoustics & dampening, and thermal insulative properties.

Glass Bubbles are lightweight

The density of Glass Bubbles ranges from 0.15 g/cc to 0.60 g/cc. In contrast to other mineral fillers such as chopped glass fibre, calcium carbonate and talc, the volume per unit of weight is therefore much greater. Replacing inorganic fillers with Glass Bubbles therefore results in composite parts with reduced density. For example, 1 kg of typical Glass Bubble material (K20) has a volume of 5000 cm3, while the equivalent weight of CaCO3 displaces only 370.4 cm3. Due to the extremely low densities of Glass Bubbles, formulation, therefore, needs to be on a volume basis rather than a weight basis. If one were simply to substitute an equal weight of Glass Bubbles for the calcium carbonate in a formulation, the volume ratio of all other ingredients would be reduced substantially. Formulating by volume instead of weight allows the proper balance of resin, filler, and reinforcement, so components can be made lighter while still maintaining a good balance of physical properties.

An older but useful example of the use of Glass Bubbles to precisely control the weight of the final part can be found in the manufacturing of bowling balls. Here, the inner cores of bowling balls are prepared using a cast polyester resin. The more Glass Bubbles used in the resin, the lower the density of the bowling ball. Therefore, the final weight of the bowling ball can be adjusted precisely and easily by adjusting the volume concentration of Glass Bubbles in the resin. Importantly, the addition of Glass Bubbles does not affect the stability of the resin, and the resin mixture remains free-flowing. As this simple example highlights, Glass Bubbles have more to offer advanced composite materials besides the obvious density reduction. In the next section, we will explore the secondary benefits and how they relate to the unique physical characteristics of Glass Bubbles.

When incorporating Glass Bubbles into a composite, one is essentially replacing a fraction of resin and/or solid fillers with uniform and microscopic pockets of air. The replacement of resin by air results in some unique side effects.

For example, the reduction of mass in turn reduces the heat capacity of the resin, which in turn results in shorter cooling times allowing parts to be produced faster. Moreover, the composite’s coefficient of linear thermal expansion (CLTE) decreases. The low CLTE means that larger composite parts can be manufactured, and these are less prone to deformation during cooling, also known as warpage.

The low CLTE can also provide benefits in the finished parts. For example, solid parts engineered using Glass Bubbles (e.g. roofing trims) will be less prone to cracking when exposed to hot/cold cycles.

In a similar vein, the thermal conductivity is lowered by the presence of Glass Bubbles. The resulting thermally insulative parts find extensive use in energy-saving applications (e.g. bathtubs which keep water warm for longer) and also add value to various consumer goods (e.g. steering wheels or shower trays which are warm to the touch).

Replacing resin and solid fillers with hollow Glass Bubbles also lowers the calorific content of the composite part. A useful side effect of this property is that fire retardant performance is improved by the introduction of hollow Glass Bubbles – simply put there is less material to burn – resulting in better fire ratings. Recently researchers also discovered secondary mechanisms by which the hollow nature of Glass Bubbles leads to a fire hazard reduction, for example in rigid foams.

The hollow nature of the Glass Bubbles further impacts the composite’s interaction with light and sound waves. This property finds its use in specialised applications such as acoustic damping.

Glass Bubbles, as the name implies, are perfectly spherical. Glass Bubbles therefore have the lowest possible surface to volume ratio of any filler. As a result, Glass Bubbles require less resin to be wetted out compared to non-spherical fillers. In many cases this means that the resin content can be lowered, resulting in cost savings and reduction of VOC emissions.

Another side effect of the spherical nature of Glass Bubbles is that the effect on the viscosity of the resin is minimised. This property is often described as a ‘ball-bearing’ effect. A better flowing resin not only allows parts to be produced more quickly, but it also results in a more isotropic filling of the mould. This in turn leads to composite parts in which stresses are more uniformly distributed. In contrast, angular fillers such as talc or glass fibres tend to interlock at higher loadings resulting in stress concentrations and fracture points in the cured part.

A great example of a technology that has successfully exploited the low viscosity impact of Glass Bubbles is Reaction Injection Moulding (RIM). RIM is a manufacturing process in which liquid polyurethane or polyurea precursors are combined, injected into a mould, and subsequently polymerised to produce the part. Since the resin is introduced into the mould as a liquid, flowability of the resin is key to ensure the precise reproduction of components with thin walls and complex geometries. Glass Bubbles work in this application to maintain flowability and to reduce the density of the parts, typically alongside heavier reinforcing fillers such as acicular Wollastonites.

Glass Bubbles are closed spheres consisting of a chemically stable soda-lime-borosilicate ‘shell’, so they are intrinsically stable toward heat damage and chemical degradation. Glass Bubbles can therefore be added into most resin systems including polyester, epoxy, and polyurethane. Their size, shape, and chemistry will not be affected by processing conditions such as temperature, humidity, nor will their properties change over time, such as during storage. The dimensional and chemical stability of Glass Bubbles is a unique advantage over other lightweight fillers such as plastic microspheres.

The stability of Glass Bubbles is particularly useful in applications in which there is some delay between mixing and curing of the resin formulation, which includes epoxy or polyester marine putties, adhesives, sealants, and polyurethane structural foams.

Glass Bubbles can withstand high external pressures due to their spherical shape and chemical make-up. The strength of Glass Bubbles quantified as the isostatic crush strength, which is dependent on the grade and varies between 100 to 30 000 PSI. Since the crush strength of a specific grade depends greatly on the wall thickness, the crush strength and density of the grade are inversely related. As a result, the selection of a grade of Glass Bubble for a specific application is usually determined by the crush strength required to survive the processing during manufacturing of the part.

Sheet moulding compound (SMC), the most prominent mass manufacturing technique to produce large composites structures, is a great example of a process in which the high strength of Glass Bubbles is of benefit. SMC is produced in sheets that consist of a thermosetting resin combined with glass fibres and other fillers. The SMC is moulded by part manufacturers under high pressure and subsequently cured. As described in the introduction, the automotive industry relies on SMC to fabricate both external surfaces (body panels, roofs), as well as internal panels (engine housing, spare tire wells, floorboards). SMC is also widely used in structural applications ranging from trench covers to lightweight roofing panels.

Author: Koen Nickmans , Ph.D.